Skidway Systems

Single & double lipped seals used in conjunction with rotary, reciprocating and oscillating shafts.

Made in Britain

Skidway Systems for Heavy Load Movement

Crossflon® skidway systems are used to aid the skidding of topsides, jackets and other heavy fabrications. A structure weighing in excess of 47,000 tonnes has been successfully loaded out on a Crossflon® skidway system.

We offer a range of Crossflon® skidway plates to suit customers individual requirements. A typical Crossflon® skidway plate consists of 2.5mm thick dimpled Crossflon® XF225 sheet hot cure factory bonded under controlled conditions to a 3mm thick carbon steel plate.

Crossflon® skidway plates are normally manufactured with a 25mm welding lip. This prevents the Crossflon® XF225 from being damaged when the Crossflon® skidway plates are tack welded into position. The PTFE / steel bond line and all upper exposed carbon steel surfaces are generally supplied coated with paint to protect against corrosion.

We offer Crossflon® XF225 with dimples spread uniformly across the skidding surface. The purpose of the dimples is to retain Crossflon® XF500, an additional lubricant, during the construction periods and to assist in reducing the static and dynamic coefficient of friction.

Crossflon® skidway plates are generally manufactured with the edges of the Crossflon® XF225 chamfered to aid the transition of the timber skid shoes during a load-out or launch operation.

Typical Configurations

Images are for illustrative purposes only. Typical configurations shown. Alternative arrangements are available, please contact us for more information.

Skidway Plate – Dimpled

Typical Assembly:

2.5mm thick dimpled Crossflon® XF225 bonded to a 3mm thick carbon steel plate.

Typical Dimensions:

Crossflon® XF225: 950mm x 450mm.

Carbon Steel: 1000mm x 500mm.

Method of Installation:

Tack welding.

- Dimpled Crossflon® XF225

- Carbon / stainless steel

Skidway Plate – Dimpled & Chamfered

2.5mm thick dimpled Crossflon® XF225 bonded to a 3mm thick carbon steel plate.

Typical Dimensions:

Crossflon® XF225: 950mm x 450mm.

Carbon Steel: 1000mm x 500mm.

Method of Installation:

Tack welding.

- Dimpled Crossflon® XF225

- Carbon / stainless steel

Lubrication Systems

Crossflon® XF500 is a water repellent grease primarily developed as a lubrication aid for Crossflon® skidway plates, but also suitable for use in general engineering applications where low coefficient of friction and reduction in shear energy is required. It offers technical and commercial advantages over conventional greases such as silicone oil.

We recommend the use of Crossflon® XF100 membrane to reduce the initial static friction caused by absorbent timber skid shoes, lengthy construction periods, uneven loading and construction site debris.

Skidway System – Fabrication Yard

- Crossflon® skidway plates – dimpled & chamfered.

- Crossflon® XF500 lubricant.

- Crossflon® XF100 membrane.

Skidway System – Launch Barge

- Crossflon® skidway plates – dimpled & chamfered.

- Crossflon® XF500 lubricant.

Speak To One Of Our Experts Today

Installation Guide

Stage 1

Crossflon® skidway plates are tack welded to the skid beam generally in an offset configuration. This is to distribute pressure more evenly during a load-out or launch operation.

Stage 2

Crossflon® XF500 lubricant is applied to the surface of the Crossflon® XF225 and then a layer of Crossflon® XF100 membrane is rolled into position.

Stage 3

Once the Crossflon® XF100 membrane has been installed, the timber skid shoes can be lowered into place for construction to commence.

Skidway Systems – Technical Data

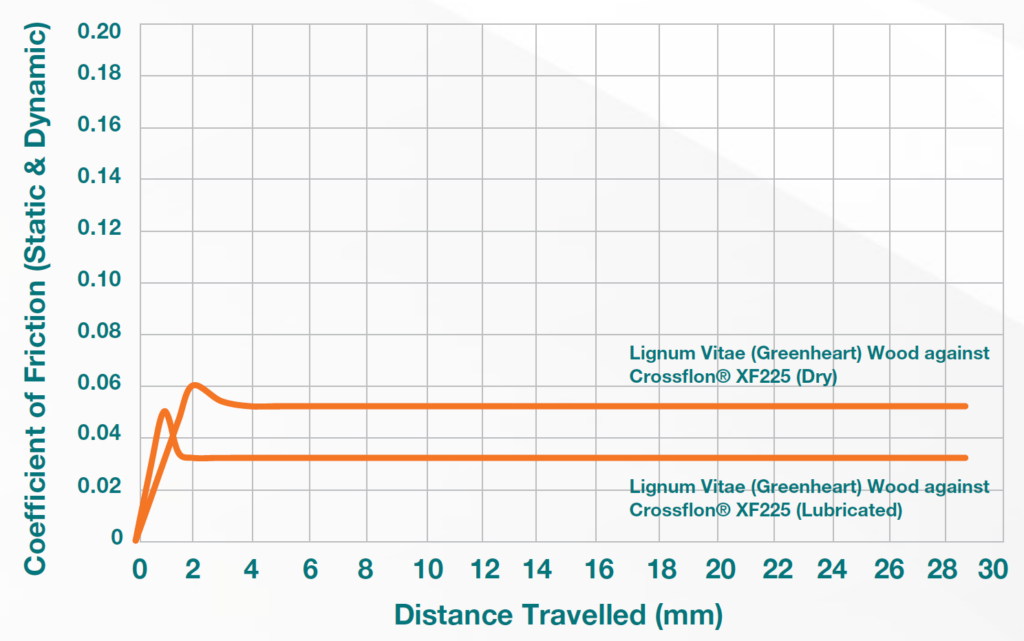

Figure 1: Coefficient of Friction (Static & Dynamic) vs. Distance Travelled

Typical coefficient of friction values are 5 to 8% for static (breakout) and 2 to 5% for dynamic (skidding). These values are based upon the correct installation of the Crossflon® skidway plates, surface finish of the timber skid shoes and the application of a Crossflon® lubrication system.

Actual coefficient of friction values recorded during the load-out of a 32,000 tonne jacket on a Crossflon® skidway system were 5% for static (breakout) and 3% for dynamic (skidding).