Manlid seals are used to leak proof the hatch. With excellent repeatability opening and closing cycles, whilst controlling emissions and protecting the cargo from external contamination.

Encapsulated seals are particularly valuable in applications involving aggressive chemicals, extreme temperatures. The sealing material is fully encased in a protective layer, enhancing its chemical resistance, durability, and overall performance.

“PHENOMENAL PERFORMANCE, INNOVATIVE TECHNOLOGY AND

THE ULTIMATE IN PRECISION ENGINEERING”

Manlid Seal Braided Solid Core

Manlid Seal Braided Silicone Core

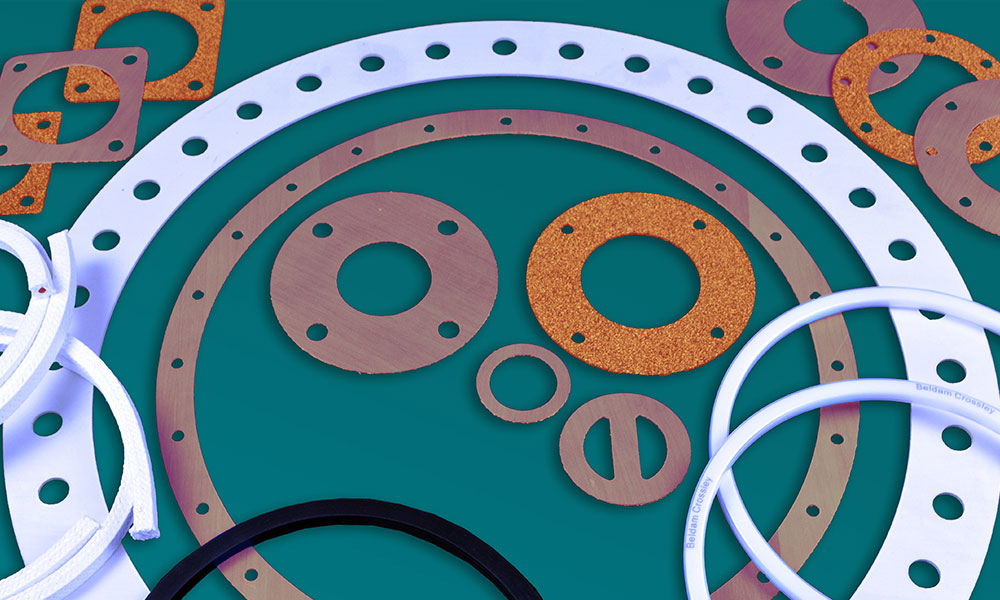

Pilot® Precision Gaskets

Designed for light oils and petrochemicals

- Compressed non-asbestos fibre sheet for general service applications, steam and oils

- Filled and expanded PTFE sheet for severe chemical duties

- Reinforced graphite and mica for high-temperature solutions

- Industrial rubber for low pressure and temperature solutions

Manlid Seal Encapsulated

Designed to seal road tanker hatches

- Resistant to a wide range of chemicals, reducing the risk of seal degradation and leaks

- Withstanding extreme temperatures, makes them suitable for many applications

- Encapsulation protects the seal from physical wear and tear

- These seals meet industry-specific compliance and safety standards

PTFE Components

Designed for light oils and petrochemicals

- A vast range of high quality, UK manufactured Crossflon®PTFE

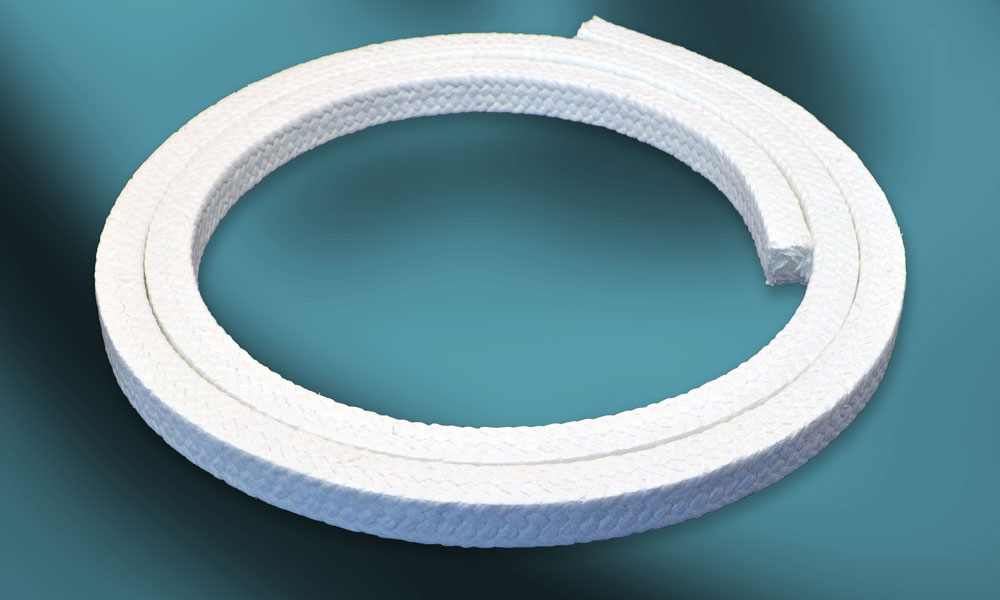

Pilot® Tank Lidpack Packing

Designed for light oils and petrochemicals

- Suitable for contact with vapour and liquid

- Superior sealing performance

- Compensates for variances in pressure and installation

- Designed for Naphtha/light oils and petrochemicals