We have dedicated and experienced CAD Design engineers. They provide a full turnkey project to serve a wide range of industries and requirements.

Focused on new product design and existing component design developments, projects can be taken from concept right through to industrialisation; utilising our comprehensive machining and engineering know-how, with the added benefit of rapid prototyping with our 3D printing capability.

Bespoke Design Expertise

Our design expertise includes, but is not limited to:

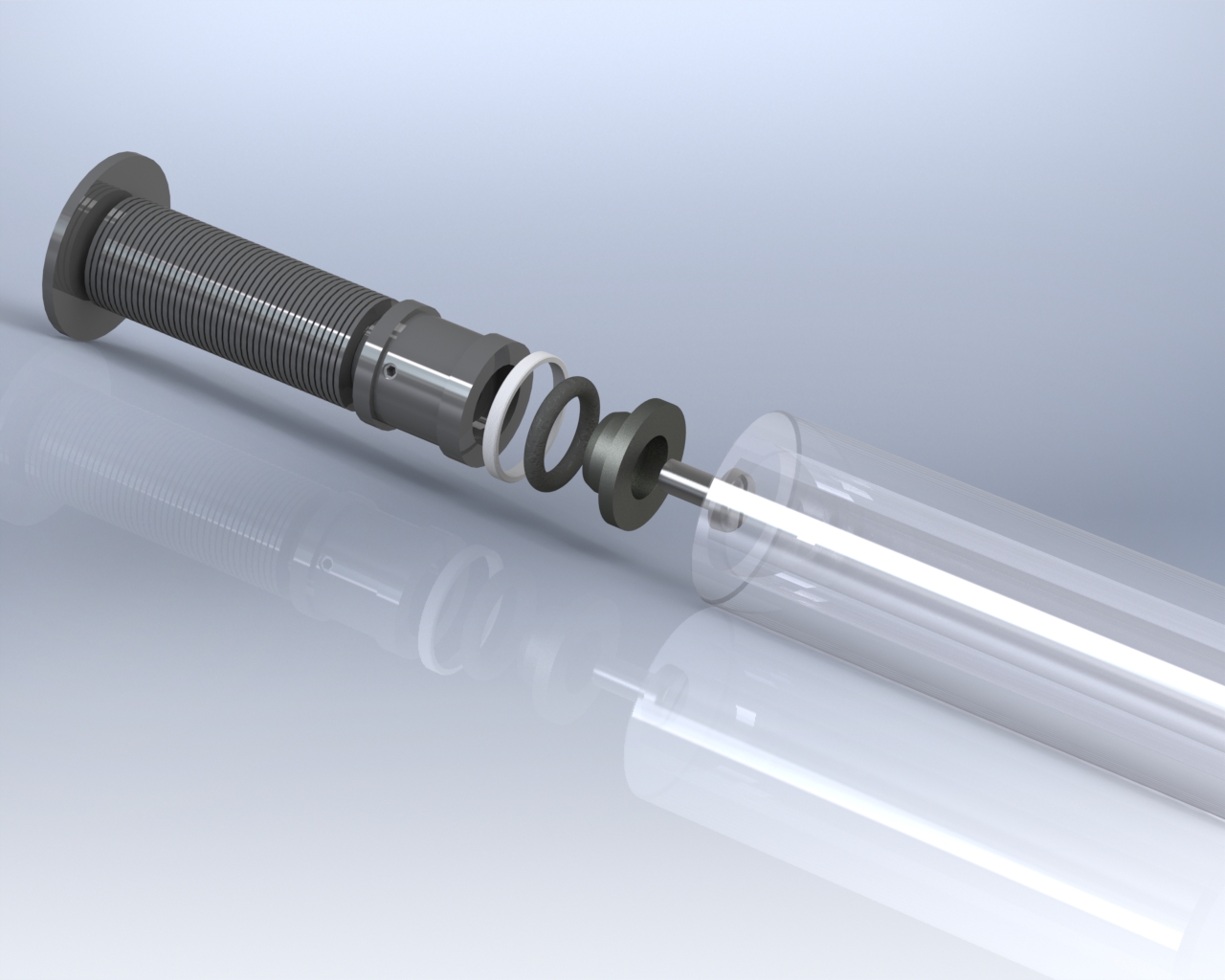

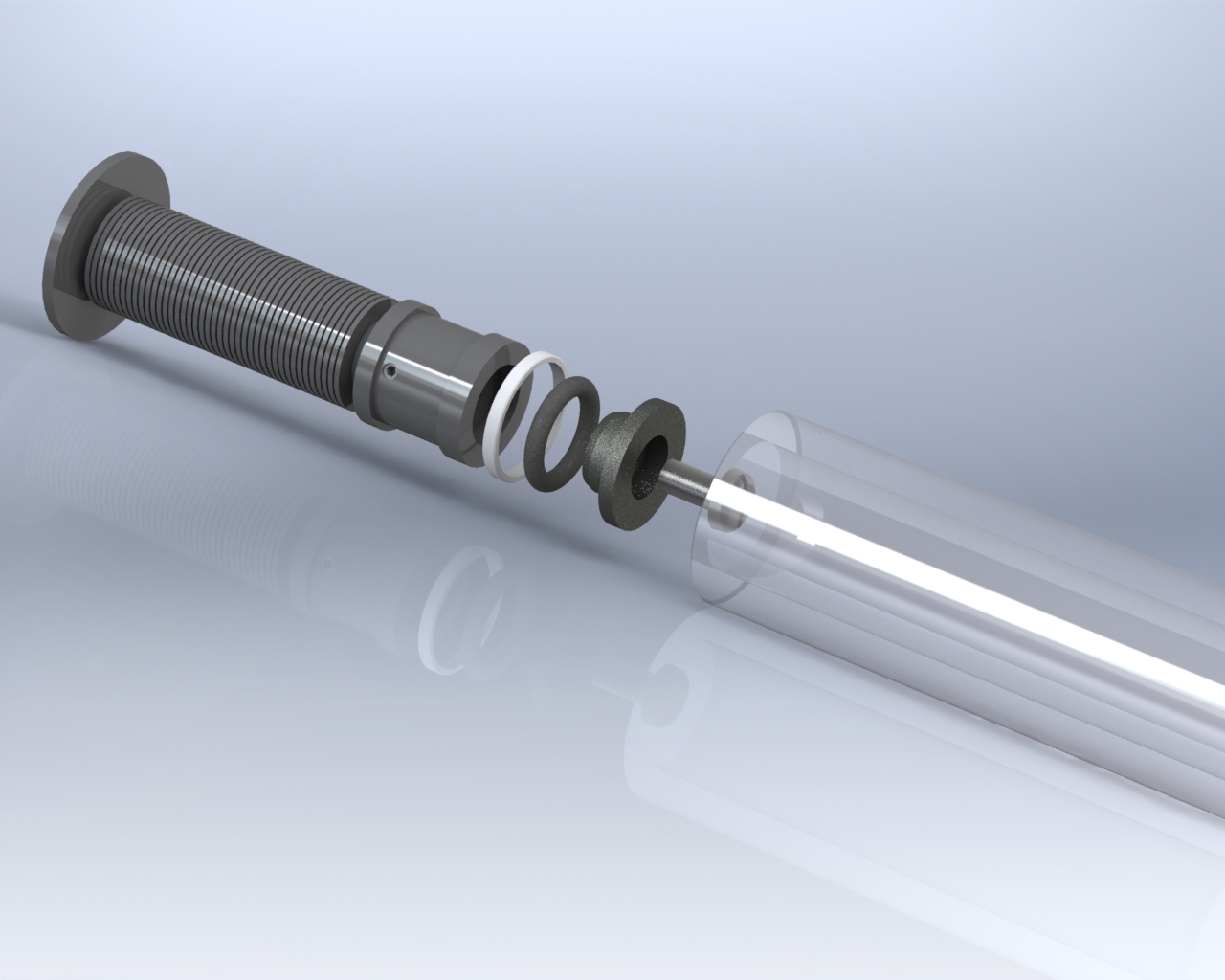

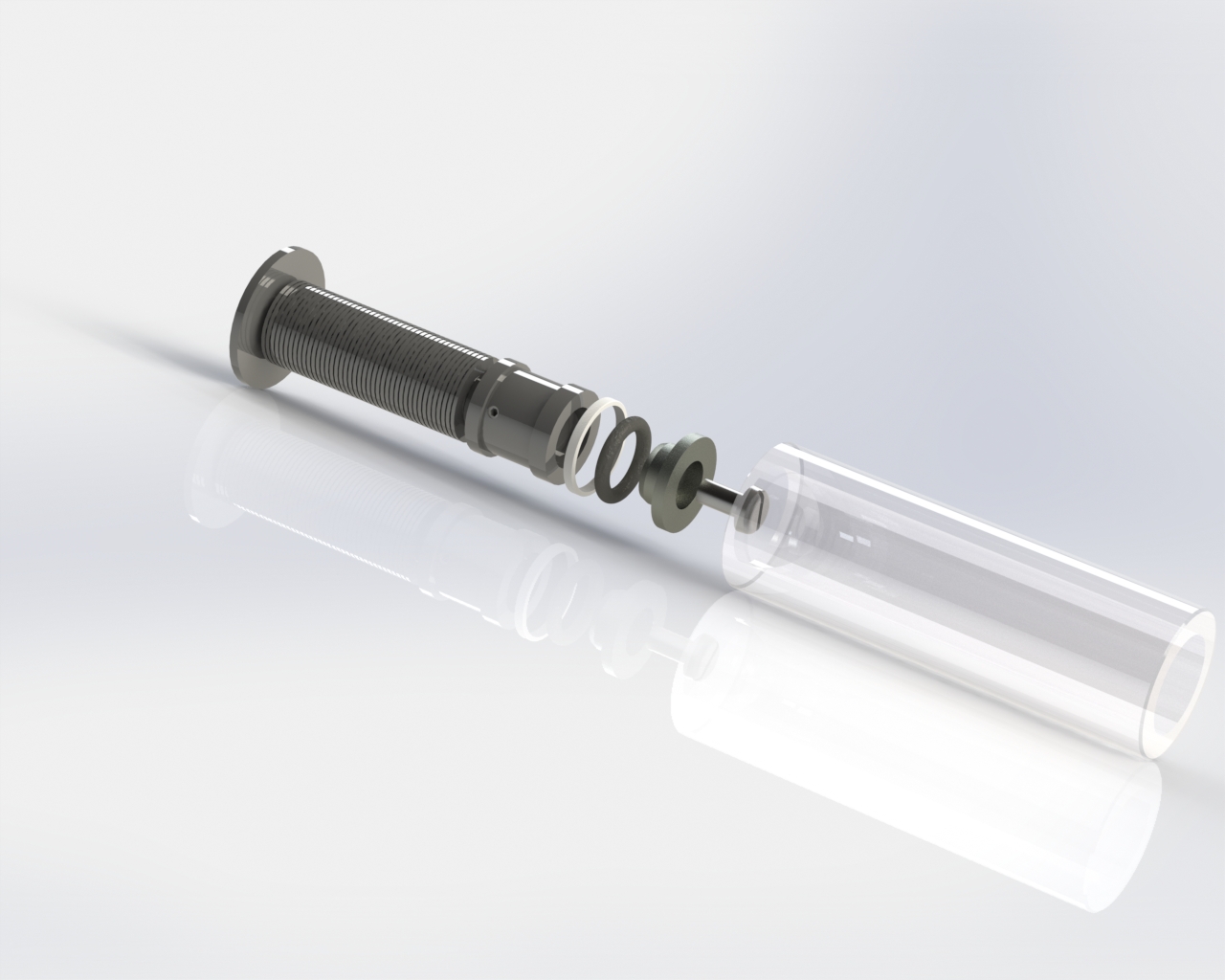

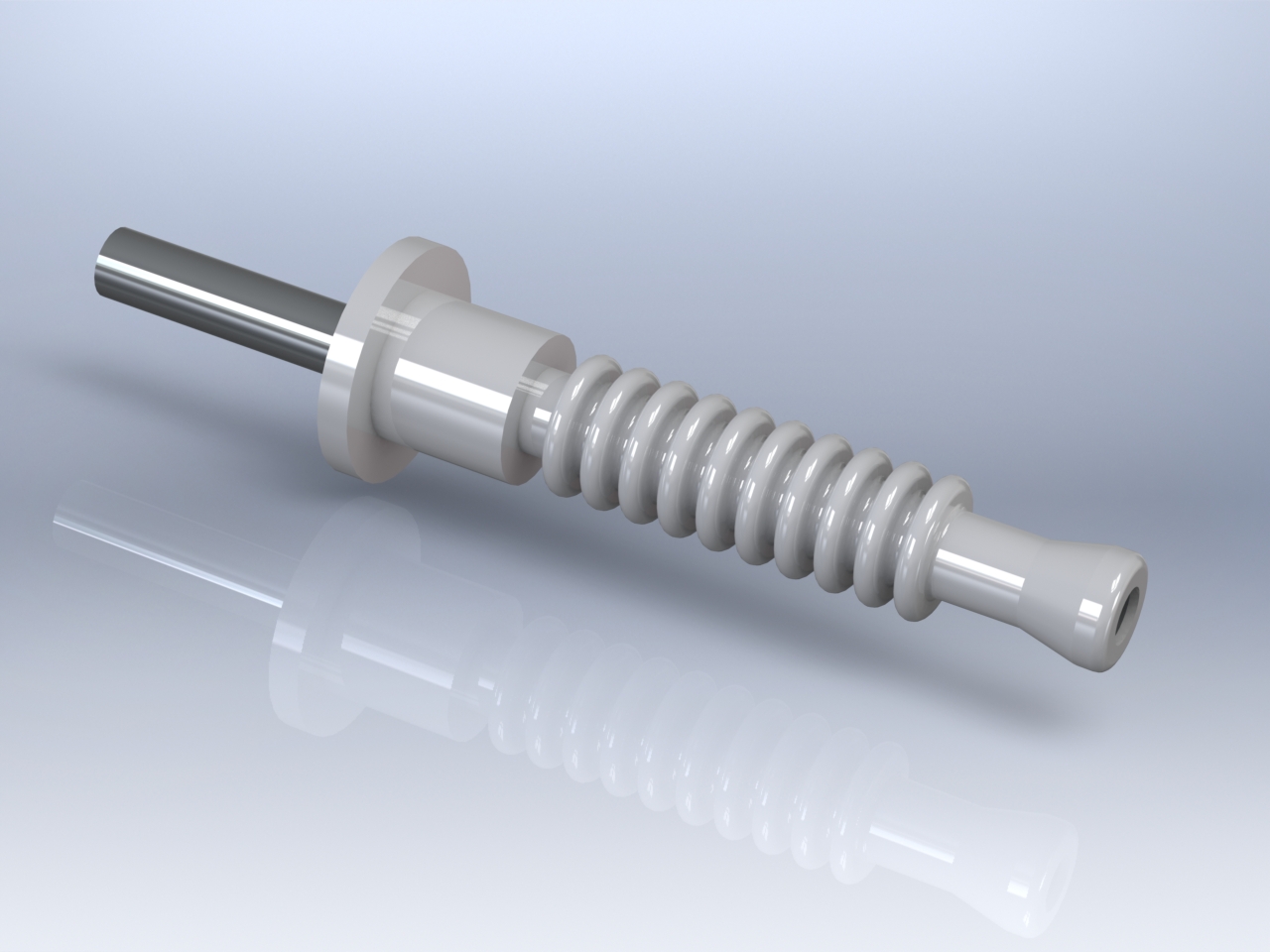

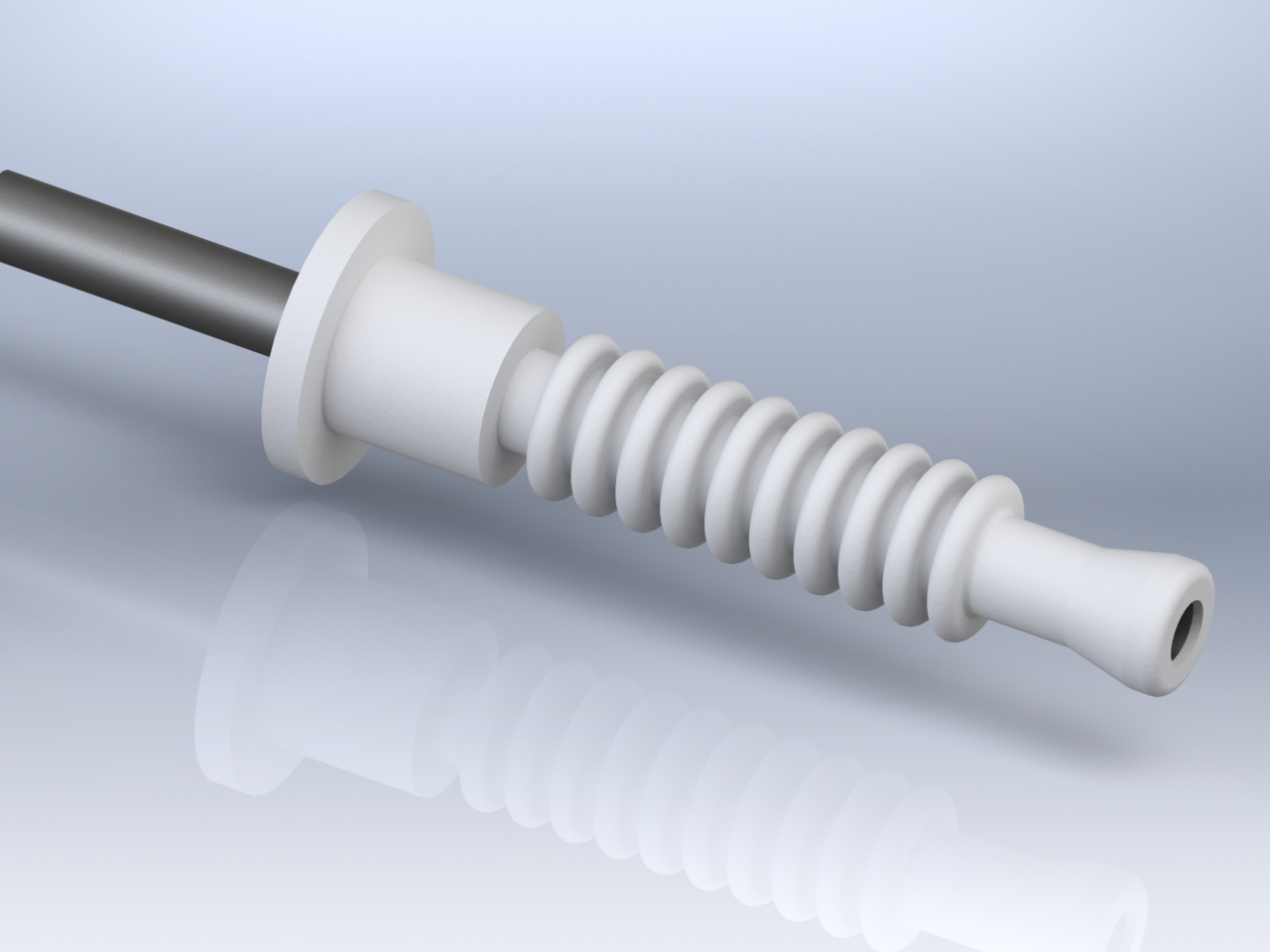

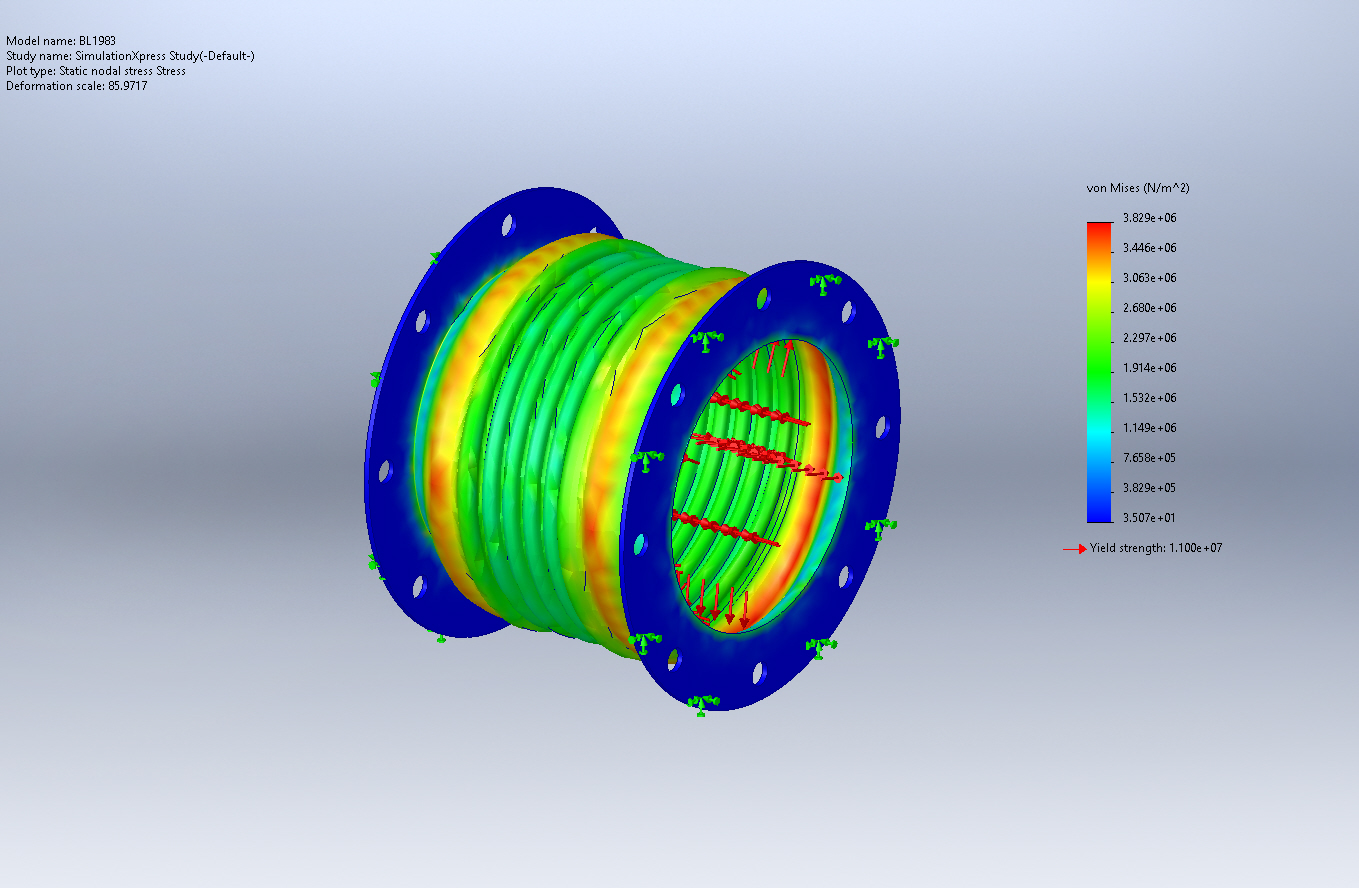

Complete bespoke design and validation for a wide range of PTFE industrial bellows. Ensuring to meet the customer’s environmental and physical requirements.

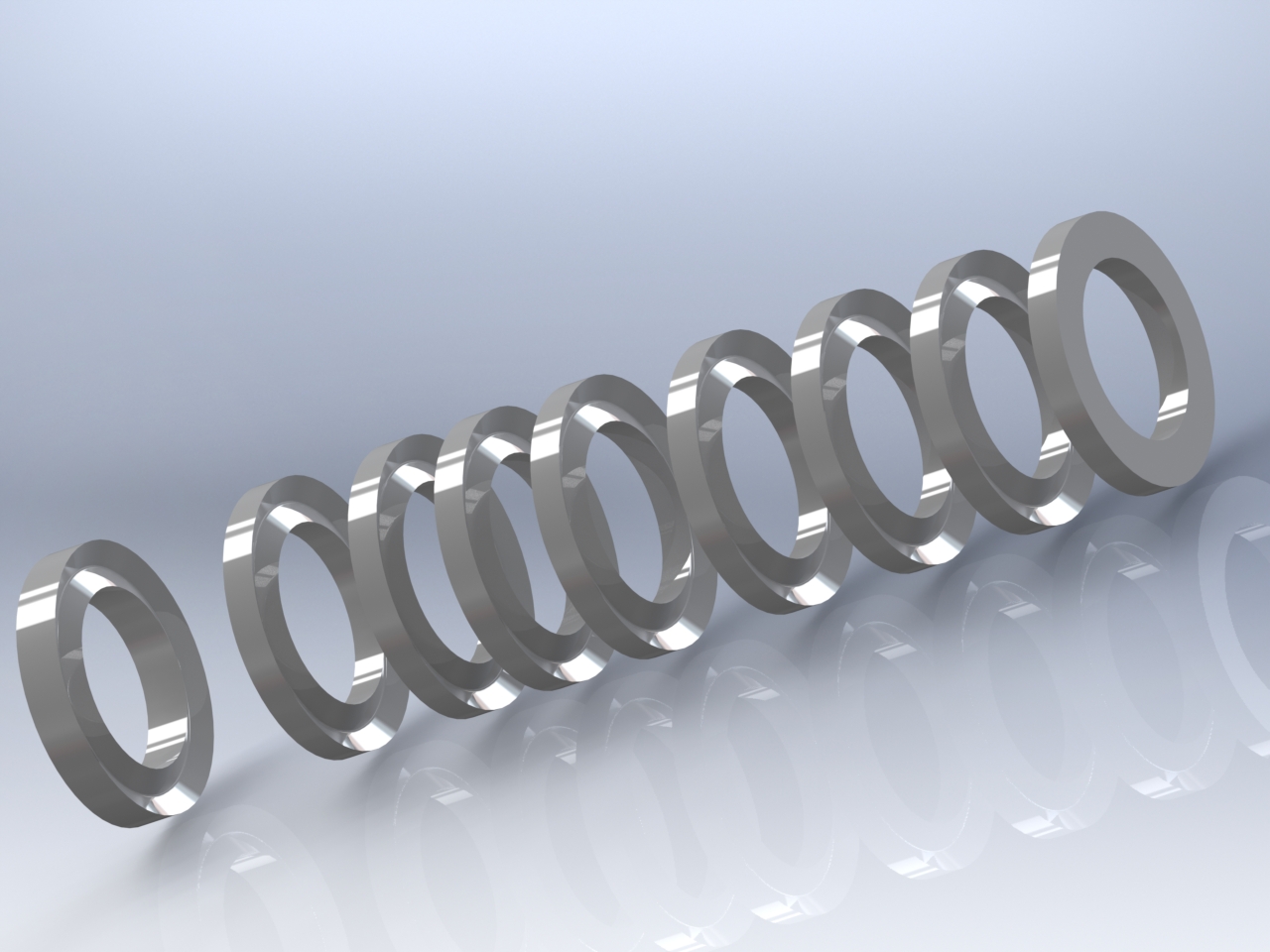

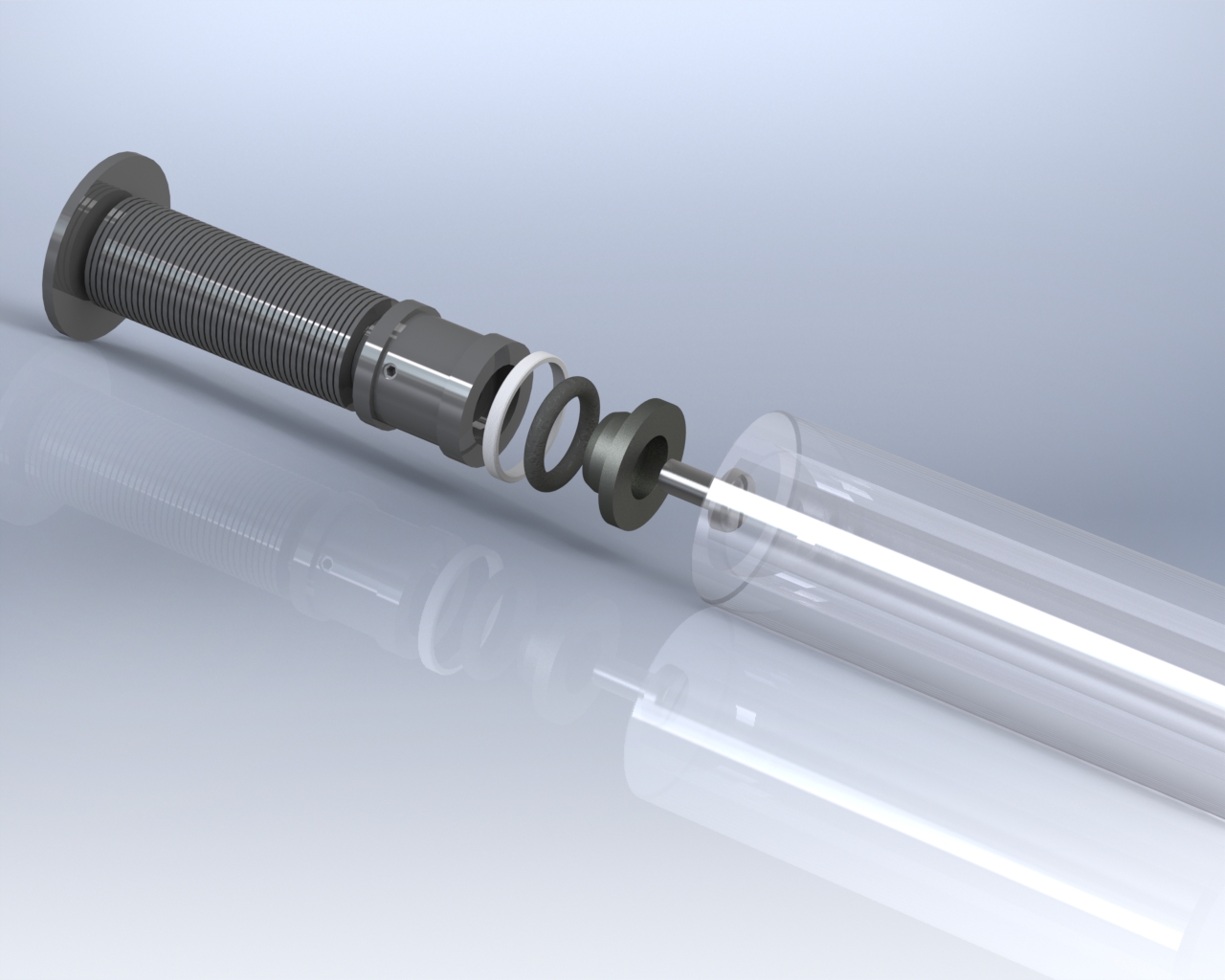

Full design and calculation of multiple sealing systems. Piston rings, static “V” rings, gaskets, valve seating, high-temperature cord seal, valve/pump packing/gland, boiler door joints and cargo hatch seals (Lidpack).

Conception and integration of high load, long life, low friction plane bearings, skidway plates and slide bearings to suit different industrial demands.

Design of tooling & fixtures for prototype component development. Allows to simulate customer applications, repeatability and cost-effectiveness of the manufacturing methods.

Design of 3D models and detailed technical drawings based on customer brief, questionnaires, customer sketches and customer samples.