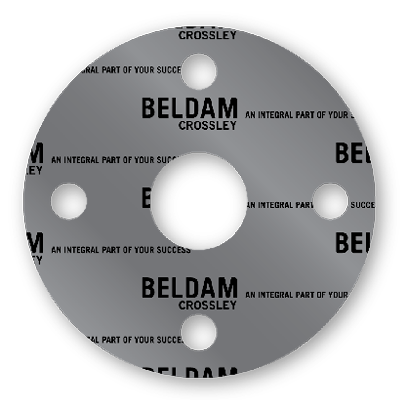

Machined Gaskets

Engineered PTFE & Polymer Gaskets by Beldam Crossley

Made in Britain

Engineered PTFE & Polymer Gaskets by Beldam Crossley

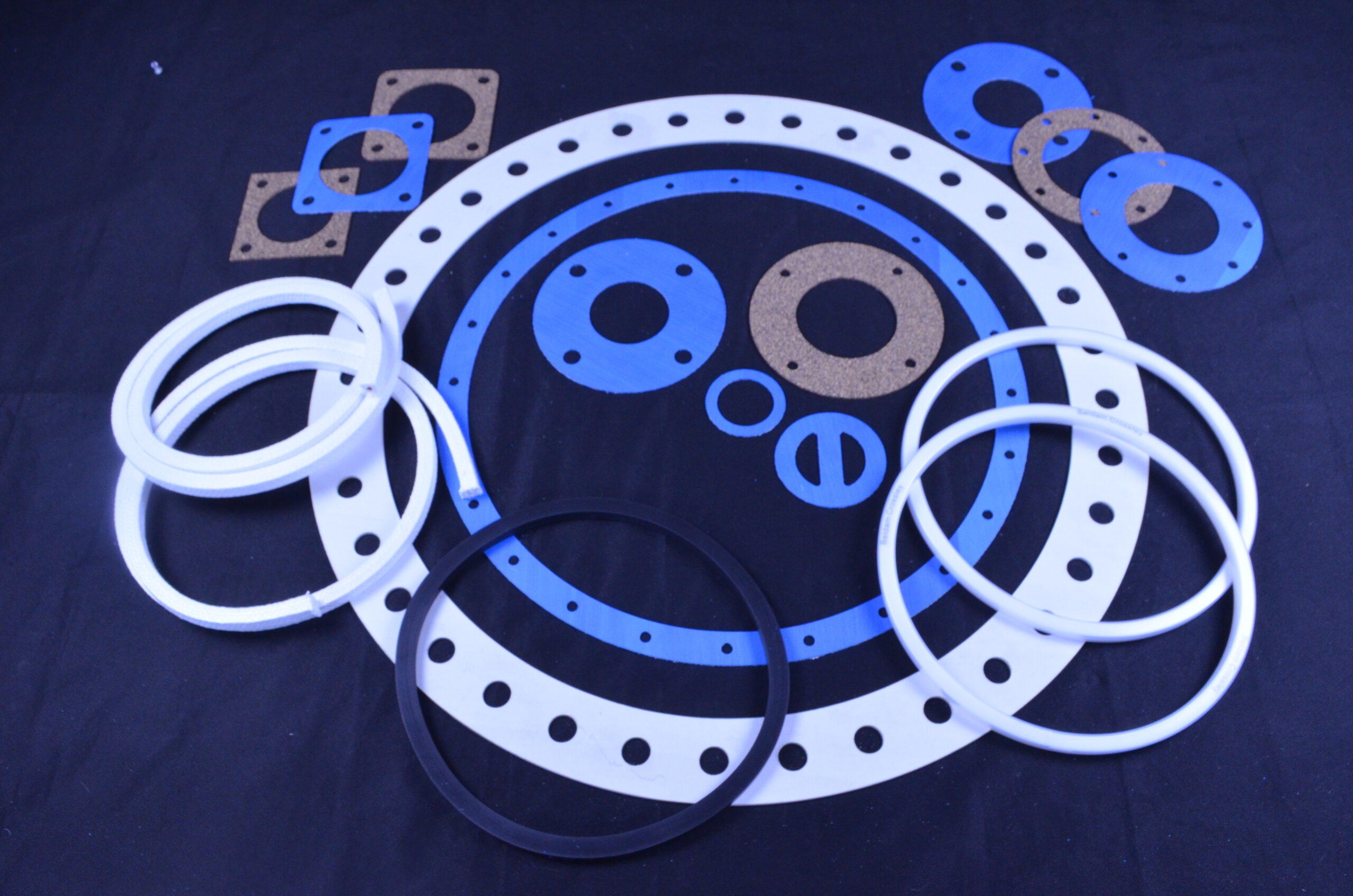

At Beldam Crossley, we design and manufacture high-performance machined gaskets to meet the most demanding industrial sealing challenges. Custom-made in the UK from premium PTFE and advanced polymer blends, our gaskets provide exceptional chemical resistance, tight sealing performance, and long-lasting durability across critical applications.

What Are Machined Gaskets?

Machined gaskets are precision-cut sealing components manufactured from solid sheets of PTFE or engineered polymers, often reinforced with fillers such as glass, graphite, stainless steel, or carbon. Unlike die-cut or molded gaskets, machined gaskets are produced using CNC machining, allowing for tight tolerances, custom geometries, and consistent quality across complex designs.

They are also referred to as:

- CNC Gaskets

- Precision-Cut Gaskets

- Engineered Polymer Gaskets

- Custom PTFE Gaskets

- Solid Gasket Rings

Key Features and Capabilities

Tight tolerance accuracy

Ideal for OEM components, precision assemblies, and high-pressure sealing systems.

Wide range of materials

Including virgin PTFE, glass-filled PTFE, graphite-filled PTFE, carbon-filled PTFE, PEEK, and other advanced polymers.

Versatile configurations

Round, oval, rectangular, slotted, or fully bespoke gasket profiles.

Machining expertise

Designed for performance in extreme pressure, temperature, and chemical environments.

We machine gaskets in-house at our UK facility using state-of-the-art CNC technology—enabling fast turnaround, repeatable quality, and full control of dimensional integrity.

Applications of Machined Gaskets

Our machined gaskets are trusted across multiple sectors, including:

Chemical processing plants

- Pharmaceutical manufacturing

- Subsea and offshore engineering

- Food and beverage production

- Aerospace and defence

- Power generation and renewables

- Petrochemical and refinery installations

They are frequently used in:

- Pump and valve flanges

- Reactor vessels

- Heat exchangers

- Pipeline connectors

- High-purity processing systems

Why Choose Beldam Crossley for Machined Gaskets?

Engineered Performance, Backed by Heritage With over 149 years of engineering expertise, Beldam Crossley is one of the UK’s most trusted manufacturers of high-integrity sealing components. Our machined gaskets are manufactured to exacting standards, tailored to your specific operational conditions.

Custom Material Blends

We offer fully customisable gasket solutions using proprietary blends of PTFE, PEEK, and other polymers—enhanced with glass, graphite, stainless steel, carbon, or other fillers. This ensures optimal mechanical, thermal, and chemical properties for your application.

Speak To One Of Our Experts Today

Certified Quality You Can Rely On

Beldam Crossley operates to globally recognised standards:

- AS9100 (Aerospace quality standard)

- BS EN ISO 9001 (Quality management)

- BS EN ISO 14001 (Environmental management)

Every gasket we supply is backed by traceable quality and robust manufacturing procedures.

Made in the UK. Trusted Worldwide

Manufacturing from our site in Bolton, we serve industrial clients worldwide with fast lead times, expert support, and tailored engineering advice.

Typical Machined Gasket Materials

- Virgin PTFE

- Glass-filled PTFE

- Graphite-filled PTFE

- Carbon-filled PTFE

- Bronze-filled PTFE

- PEEK

- Crossflon™ performance blends

- UHMWPE and other high-grade polymers

Beyond Gaskets: Total Sealing Solutions

Beldam Crossley also manufactures:

- Envelope Gaskets

- Bellows and Expansion Joints

- Chevron Packing Sets

- Rotary, Lip and Cup Seals

- Valve Seats and Back-Up Rings

We provide a full turnkey design and production service, from initial drawings and samples through to final supply—offering exact replacements or performance-enhanced upgrades for existing components.

Get in Touch with Our Gasket Experts

Looking for a custom PTFE or polymer gasket for a complex sealing challenge? Beldam Crossley is ready to help.

Frequently Asked Questions

Machined gaskets offer tighter tolerances and better performance under extreme conditions. They’re ideal for bespoke and critical applications.

Yes. We can reverse-engineer from a sample or manufacture to your exact technical drawing, including complex geometries and surface finishes.

Industries requiring chemical resistance, purity, or high sealing integrity—such as chemical, food, marine, aerospace, and pharma—commonly rely on our solutions.