We offer Crossflon® XF225 with dimples spread uniformly across the skidding surface. The purpose of the dimples is to retain Crossflon® XF500, an additional lubricant, during the construction periods and to assist in reducing the static and dynamic coefficient of friction.

Crossflon® skidway plates are generally manufactured with the edges of the Crossflon® XF225 chamfered to aid the transition of the timber skid shoes during a load-out or launch operation.

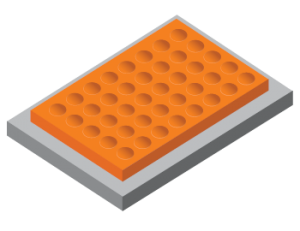

Crossflon® Skidway Plate Dimpled

Typical Assembly:

2.5mm thick dimpled Crossflon® XF225 bonded to a 3mm thick carbon steel plate.

Typical Dimensions:

Crossflon® XF225: 950mm x 450mm.

Carbon Steel:

1000mm x 500mm.

Method of Installation:

Tack welding.

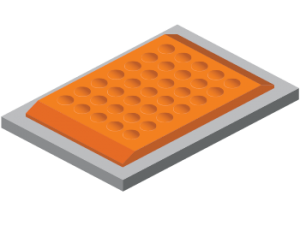

Crossflon® Skidway Plate Dimpled & Chamfered

Typical Assembly:

2.5mm thick dimpled Crossflon® XF225 bonded to a 3mm thick carbon steel plate.

Typical Dimensions:

Crossflon® XF225: 950mm x 450mm.

Carbon Steel:

1000mm x 500mm.

Method of Installation:

Tack welding.

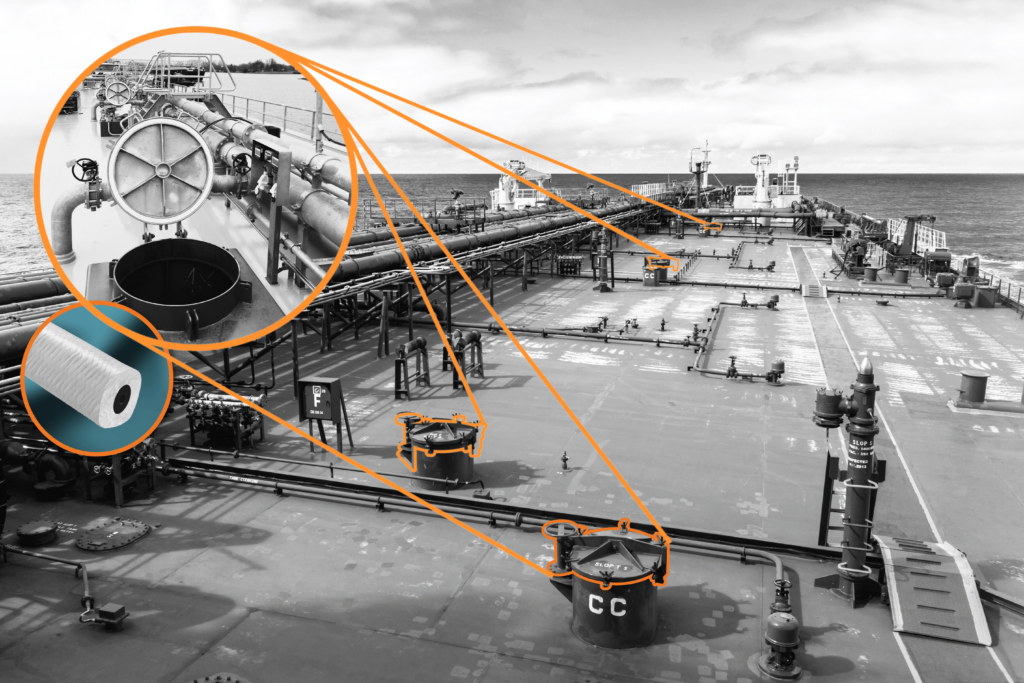

Fast, Compliant Marine Hatch Packing Seals – Now Available with 2-Day Delivery from Istanbul

Beldam Crossley Lidpack® Hatch Seal Solution for Chemical and Crude Oil Tankers

*Images are for illustrative purposes only. Typical configurations shown. Alternative arrangements are available, please contact us for more information.