This problem of inadequate packings was right on Asplan Beldam’s doorstep because of his pursuit of high steam pressures, so he bent his considerable abilities to finding a solution. His answer was the first metallic asbestos—or compound—packing. He rolled a sandwich of woven fabric and pleated white metal foil into a cylinder, like a Swiss roll, where the foil represented the filling. This cylinder was then pressure-formed into whatever cross-section—square, round, triangular—a particular application called for. Pleating the metal foil gave the packing a degree of flexibility, which enabled it to be used for situations of almost any diameter and to bend without fracture.

The new packing proved to be vastly more durable and effective in Beldam’s high-pressure engines than existing types. News of this improved performance soon spread around the marine engineering fraternity, and a number of inquiries from other steam users doubtlessly convinced Asplan Beldam that his packing had a high commercial potential. So, in 1876, he patented the packing and formed the Beldam Packing and Rubber Company to exploit it.

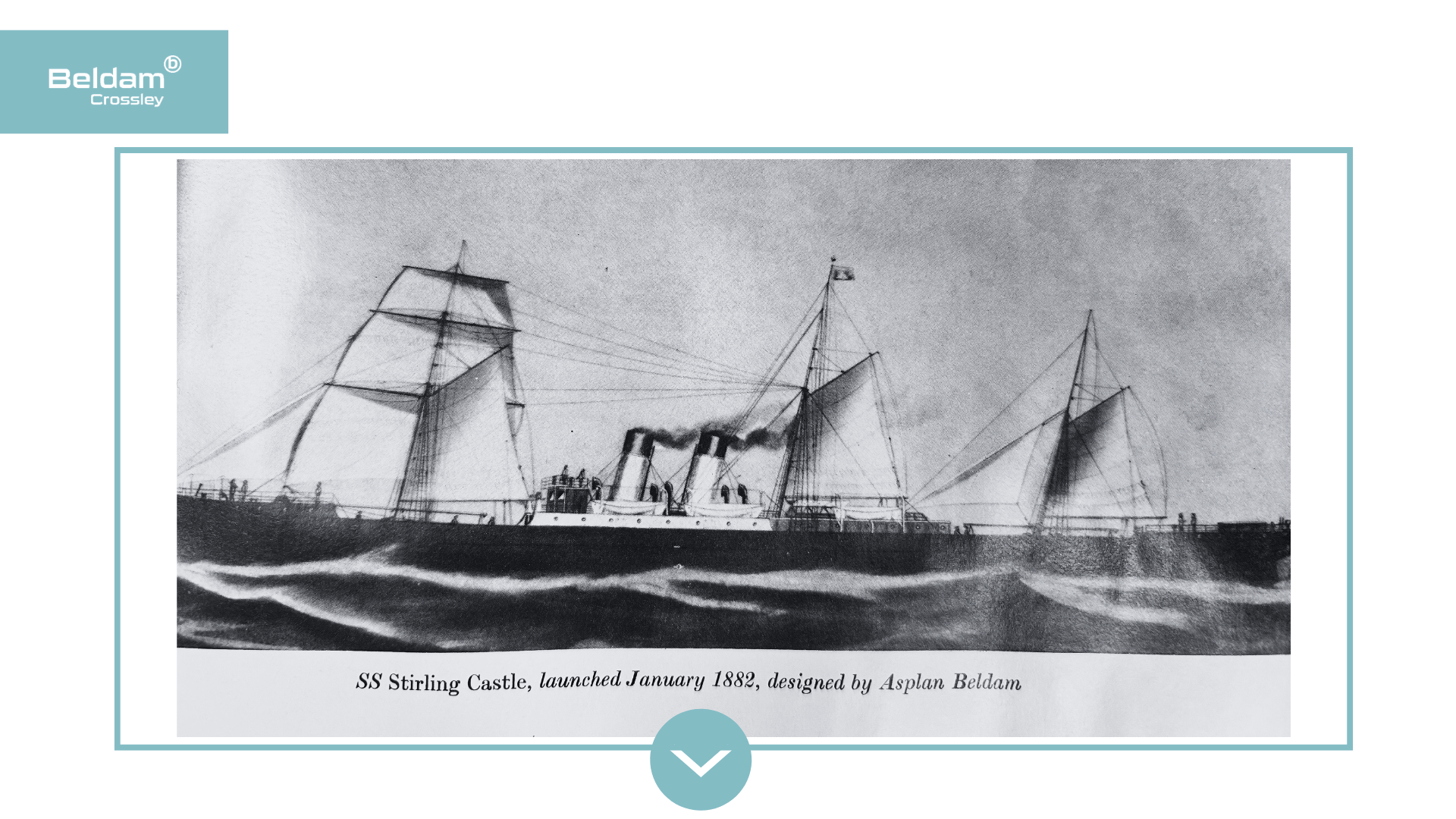

By that time, he had ceased to be the servant of any one company and had set up as a consulting engineer and naval architect in the City of London. In that capacity, he undertook numerous commissions for shipbuilders and shipowners. One of his outstanding achievements was to design and supervise the building of a ship which became the fastest vessel afloat. She was the STIRLING CASTLE—iron-hulled, screw-driven, and steaming at 100 lb. per square inch. Launched in January 1882, with a deadweight tonnage of over 6,000, she was big for her day.

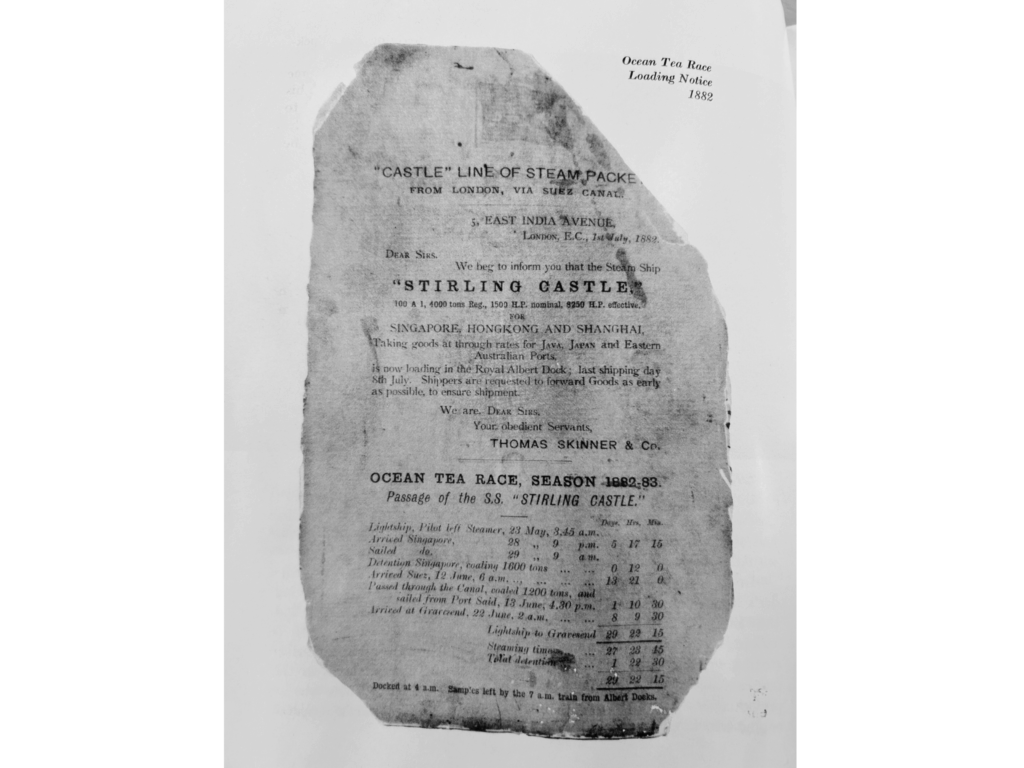

In the same year, she provided a splendid vindication of our founder’s high-pressure designs—and of Beldam packings too—by leaving the China tea port of Woosung with 6,000 tons of tea on May 23 and arriving in London on June 22—effectively a 30-day trip, with a steaming time of just under 28 days. That was a remarkable performance when most steamers took anything from 40 to 60 days: the previous record by a steamer was 36 days. To show that this was no engine-wrecking, flash-in-the-pan effort, the STIRLING CASTLE repeated the feat in 1883, leaving Hankow on May 22 and arriving with clockwork precision in London on June 22.