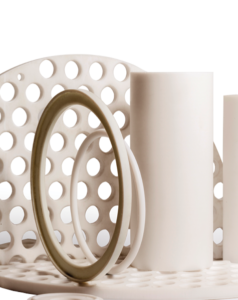

Chemically Inert PTFE Seals for High-Corrosion, High-Temperature Applications

Sealing systems within chemical plants must operate reliably in corrosive environments that degrade elastomers and standard polymers. Concentrated acids, alkalis, oxidisers and solvents attack most sealing materials, resulting in leakage, downtime and contamination risks.

Beldam Crossley designs and manufactures PTFE seals and gaskets engineered to perform reliably under extreme media exposure, temperature, and pressure. Using our Crossflon® materials, we provide long‑lasting sealing solutions for pumps, flanges, valves, pipework, mixers, and reactors.

Selected Crossflon® Materials for Sealing

- Crossflon® 1000

Maximum chemical resistance and purity. Used for sealing high-corrosive media where contamination control and inertness are essential. - Crossflon® 703

Enhanced wear resistance suitable for dynamic and high load applications in pumps, compressors, mixers and valves. - Crossflon® 603

High rigidity and creep resistance under pressure. Ideal for static gasket applications and compressed flange sealing.

Compared with elastomers such as Silicone, EPDM, and FKM, as well as plastics like UHMWPE or PVC, Crossflon® grades will not degrade, soften, or swell. They are engineered to maintain dimensional stability and sealing integrity even in highly aggressive environments.

Applications Include

- pipe flanges and compressor gaskets

- dynamic pump seals

- valve seats

- shaft seals in mixing vessels

- dosing and transfer systems

- reactor and vessel interfaces

Performance Advantages

- inert to strong acids/bases and oxidisers

- wide temperature capability

- reduced cold flow with filled grades

- food/pharma compliant grades available

In modern petrochemical facilities, reliability is everything. Crossflon® sealing materials reduce process risk, extend maintenance intervals, and improve operational safety across aggressive media handling.

PTFE Seals & Gaskets for Aggressive Media for the Petrochemical Industry

|

CROSSFLON® MATERIAL

|

TYPICAL PRODUCTS

|

KEY CHARACTERISTICS

|

|---|---|---|

|

1000 |

High-purity gaskets, diaphragms, bellows, sight glass seals, Insulating bushes/spacers |

Maximum chemical resistance, inert to acids/solvents/bases, low contamination |

|

703 |

Dynamic pump seals, compressor seals, high-load/pressure flange gaskets, valve stem packing, wear pads |

Enhanced thermal conductivity, reduced wear rates of wear. Good physical properties whilst retaining most of the chemical resistance of Virgin PTFE |

|

603 |

Static flange gaskets, compressed sealing rings, valve seats, mixer bushings, pump housings |

Excellent balance of chemical, electrical insulation and mechanical properties. For applications requiring low cold flow and high compressive rigidity |

|

403 |

Aggressive media seals, corrosive pipeline gaskets, reciprocating piston seals, compressor rings |

Similar properties to Crossflon 703, but with ultra-low coefficient of friction. Ideal for dry running or poorly lubricated applications |

|

1404 |

High-temperature sealing elements, housing seals, compressor rings, pump/mixer seals |

Maintains seal integrity under high heat with excellent deformation resistance, kind to mating surfaces |

For more information speak to one of our expert engineers today