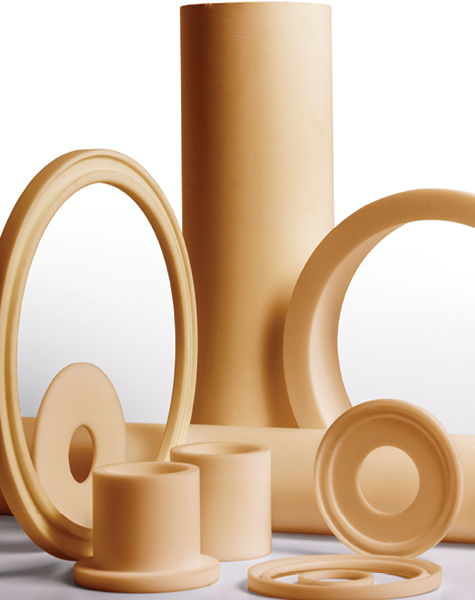

Rotary Seals

Precision-Engineered Rotary Seals for High-Performance Applications

Made in Britain

Leading Rotary Seal Manufacturer – Custom Solutions for Extreme Conditions

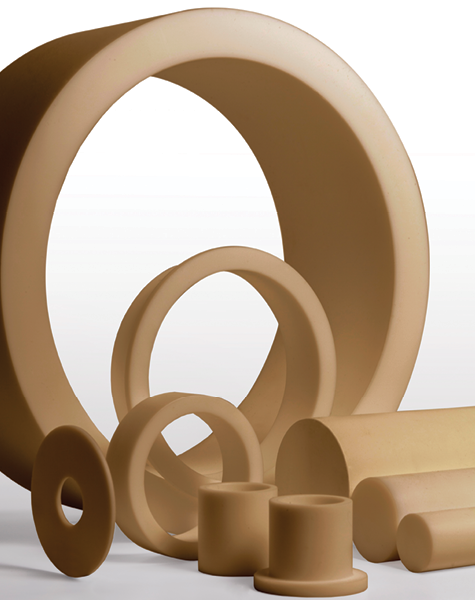

As a trusted rotary seal manufacturer, Beldam Crossley specializes in precision-engineered rotary seals designed to withstand high-speed rotation, high temperatures, and aggressive media. Our custom rotary seals provide superior durability, leak-proof performance, and extended service life, making them the preferred choice for OEMs and critical industries worldwide.

With decades of expertise in advanced sealing solutions, we manufacture rotary seals that optimize efficiency, minimize wear, and deliver long-term reliability.

Why Choose Beldam Crossley as Your Rotary Seal Manufacturer?

For nearly 150 years, Beldam Crossley has been at the forefront of precision-engineered sealing solutions. As a leading rotary seal manufacturer, we design and produce custom rotary seals that enhance system performance, minimize downtime, and withstand even the harshest industrial environments.

We adhere to the highest industry standards:

- AS9100 Quality Standard – Ensuring aerospace-grade precision and reliability.

- ISO 14001 Environmental Standard – Commitment to sustainable and eco-friendly manufacturing.

Rotary Seal Features

Withstand high temperatures

Superior durability

Leak-free performance

Extended life service

High performance materials

High industry standards

UK manufactured

The Beldam Crossley Advantage – Industry-Leading Rotary Seal Manufacturer

- Custom-Engineered for Exact Fit & Function

Unlike standard rotary seals, our custom-engineered solutions are designed to meet the precise specifications of your application, ensuring a secure and efficient seal every time. - Exclusive Crossflon® High-Performance Materials

As a leading rotary seal manufacturer, we formulate and blend our own Crossflon® engineering plastics and PTFE components, delivering superior chemical resistance, durability, and low-friction performance for extended service life. - Turnkey Rotary Seal Solutions – From Design to Production

From custom material formulation to CAD design, prototyping via 3D printing or sample manufacture, and state of the art simulation and testing , we offer a fully integrated solution tailored to your industry needs.

Polymer Experts

Beldam Crossley offer a comprehensive range of polymer and metal machining capabilities ranging from PTFE, Peak, nylons, polypropylene, steel, stainless steel and aluminium with a flexibility of manufacturing one off development prototype components to volume production batches.

The site hold a number of machines and tooling to support the polymer and metal machining customer requirements from conventional machining to CNC machining on Milling, Turning and Grinding.

High-Performance Rotary Seals – Built for Extreme Conditions

Our precision-engineered rotary seals offer:

- Exceptional Wear & Abrasion Resistance – Reducing downtime and maintenance costs.

- Superior Thermal & Chemical Stability – Withstanding high temperatures and aggressive chemicals.

- Optimized Sealing Performance – Ensuring leak-free operation and enhanced efficiency.

Custom Rotary Seals vs. Standard Rotary Seals – Why Customization Matters

As a specialized rotary seal manufacturer, we understand that off-the-shelf solutions don’t always meet the demands of critical applications. Our custom rotary seals offer:

- Perfect Fit for Your Equipment – Eliminating issues caused by poorly fitting standard components.

- Enhanced Durability & Performance – Withstanding harsh operating conditions.

- Low Friction & Energy Efficiency – Reducing heat buildup and wear.

- Corrosion Resistance – Resisting rust and degradation in demanding environments.

- Custom Material Formulation – Engineered with the ideal polymer blend for your specific application.

- Cost-Effective & Sustainable – Long-lasting solutions that reduce maintenance and replacement costs.

Speak To One Of Our Experts Today

Industries & Applications – Trusted Rotary Seal Manufacturer Across Sectors

Our high-performance rotary seals are used across multiple industries, including:

- Oil & Gas – Precision-engineered rotary seals for drilling, refining, and gas transmission systems.

- Petrochemical & Chemical Processing – Corrosion-resistant rotary seals for aggressive fluid control applications.

- Aerospace & Defense – Lightweight and durable rotary seals for aircraft and space systems.

- Pharmaceutical & Medical – FDA-compliant rotary seals for sterile fluid management.

- Food & Beverage – Hygienic, food-grade rotary seals ensuring contamination-free processing.

- Power Generation & Renewable Energy – High-efficiency rotary seals for wind turbines, hydroelectric plants, and nuclear reactors.

- Marine & Offshore – Saltwater-resistant rotary seals for marine propulsion and offshore platforms.

- Water Treatment & Filtration – Reliable rotary seals for flow control in purification systems.

Applications – Where Our Rotary Seals Deliver Performance & Reliability

As a trusted rotary seal manufacturer, our custom-engineered rotary seals are used in:

- Hydraulic Pumps & Motors – Preventing fluid leakage and enhancing performance in high-speed applications.

- Gearboxes & Transmissions – Providing durable sealing for rotating shafts in power transmission systems.

- Compressors & Turbines – Ensuring leak-proof operation in high-pressure environments.

- Mixers & Agitators – Offering high wear resistance for continuous motion applications.

- Rotary Unions & Swivels – Enabling fluid transfer in rotating machinery.

- Propulsion & Drive Systems – Sealing critical components in automotive and marine applications.

Full-Service Custom Rotary Seal Manufacturer – From Concept to Completion

Beldam Crossley offers a complete rotary seal manufacturing service, ensuring that each component meets your exact specifications. Our process includes:

- CAD Design & Engineering Support – Developing precision rotary seals for optimal sealing performance.

- Custom Polymer Material Selection – Tailored to meet your industry’s specific demands.

- Advanced Precision Machining – Manufacturing non-standard rotary seals with tight tolerances.

- Prototyping & Sample Production – Validating performance before full-scale production.

- Rigorous Testing & Quality Assurance – Guaranteeing compliance with industry regulations.

Sustainable Rotary Seal Solutions – Performance with Environmental Responsibility

As an eco-conscious rotary seal manufacturer, Beldam Crossley is committed to sustainability. Our eco-friendly rotary seals are produced using partially recycled materials, helping industries reduce their environmental footprint while maintaining top-tier performance.

- Lower Carbon Footprint – Manufactured using sustainable practices.

- Uncompromised Performance – Designed to match or exceed traditional rotary seals.

- Supporting Green Initiatives – Aligning with your company’s sustainability goals.

Work with a Leading Rotary Seal Manufacturer – Get a Custom Solution Today

Need a high-performance, custom-machined rotary seal? As a leading rotary seal manufacturer, we provide tailored solutions to meet your exact specifications. Whether you need a brand-new design or a superior replacement for an existing component, we’ll work with you to find the perfect fit.

Don’t settle for standard – choose a rotary seal manufacturer with the expertise to deliver the perfect solution for your application. Contact us today!