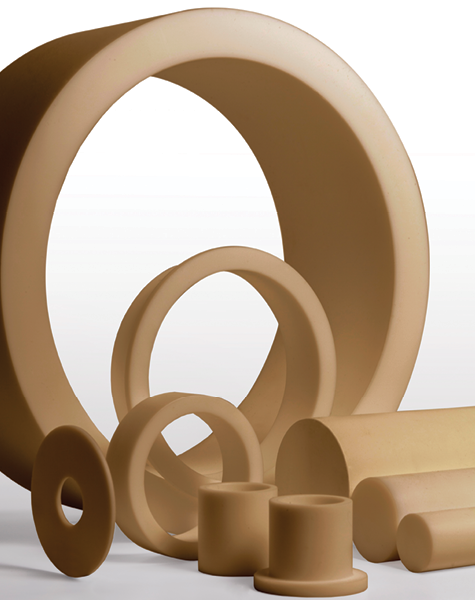

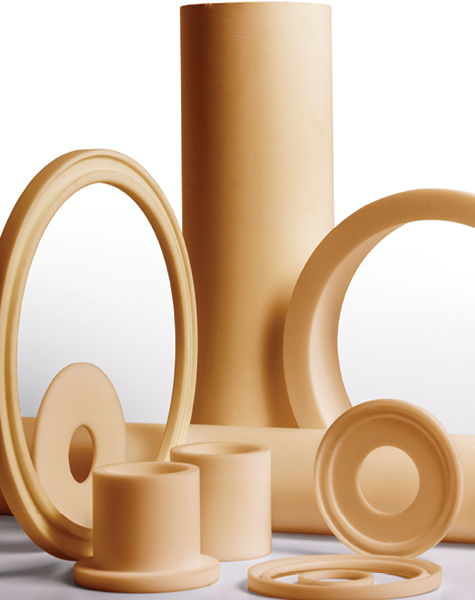

PTFE & Polymer Diaphragms

Precision-Engineered Valve Seats for High-Performance Applications

Made in Britain

Custom Machined Components from Beldam Crossley

Engineered Diaphragm Solutions for Demanding Sealing and Control Applications

Beldam Crossley is a trusted UK manufacturer of high-performance PTFE and polymer diaphragms, engineered to deliver exceptional chemical resistance, mechanical durability, and long-term sealing performance. With a legacy of over 149 years in custom component manufacturing, we provide precision-machined diaphragms tailored to meet the critical demands of flow control, actuation, metering, and separation processes.

What Are PTFE and Polymer Diaphragms?

PTFE and polymer diaphragms are flexible, chemical-resistant barriers used in mechanical and pneumatic systems to isolate media while allowing controlled movement. These components are critical in maintaining system integrity in environments involving aggressive chemicals, sterilisation, or pressure variation.

Common alternative names for diaphragms include:

- Membrane seals

- Control valve diaphragms

- Pump diaphragms

- Actuator membranes

- PTFE isolation discs

PTFE & Polymer Diaphragms Features

Exceptional chemical resistance

Inert to virtually all media including acids, solvents, and hydrocarbons

High temperature range

from -240°C to +250°C (depending on material blend)

Non-stick, low-permeability surface

Ideal for hygienic and sanitary applications

Flexible under pressure

Ideal for pulsation dampening, actuation, and isolation

Long service life

High wear resistance, even under constant flex or deformation

Customisable profile and thickness

Engineered to your specific movement, sealing, and pressure parameters

Where Are Diaphragms Used?

Beldam Crossley’s custom-machined diaphragms are used across a wide range of sectors, including:

- Chemical processing

- Pharmaceutical & biotechnology

- Food & beverage manufacturing

- Oil & gas and petrochemical

- Water treatment & filtration

- Pumps, valves, and dosing systems

- OEM control units and instrumentation

Key Features and Benefits

✔ Exceptional chemical resistance – Inert to virtually all media including acids, solvents, and hydrocarbons

✔ Temperature range: from -240°C to +250°C (depending on material blend)

✔ Non-stick, low-permeability surface – Ideal for hygienic and sanitary applications

✔ Flexible under pressure – Ideal for pulsation dampening, actuation, and isolation

✔ Long service life – High wear resistance, even under constant flex or deformation

✔ Customisable profile and thickness – Engineered to your specific movement, sealing, and pressure parameters

Custom Polymer Blends for Enhanced Performance

Our diaphragms can be manufactured from virgin PTFE or custom-engineered polymer blends incorporating:

- Glass for improved wear and dimensional stability

- Graphite or carbon for conductivity and reduced friction

- Stainless steel mesh inserts for structural support

- Elastomer backing for pressure-assisted actuation

We use our proprietary Crossflon™ range of PTFE and engineering polymers, ensuring your component delivers optimal performance in your precise operating conditions.

Speak To One Of Our Experts Today

Precision Machined to Your Requirements

Every diaphragm is CNC-machined in-house at our UK facility to ensure tight tolerances, consistent quality, and repeatable performance. Whether you need a one-off prototype, a small production run, or full-scale supply, Beldam Crossley delivers with precision and speed.

We can:

- Reverse engineer from an existing sample

- Manufacture directly from your drawing or CAD file

- Provide complete design consultancy for new applications

Why Choose Beldam Crossley?

- 149+ years of engineering heritage

- In-house manufacturing in the UK

- Fast turnaround and responsive technical support

- Trusted by leading global brands in critical industries

- AS9100, ISO 9001, and ISO 14001 accredited

Beldam Crossley is more than a component supplier—we’re your long-term engineering partner, committed to quality, sustainability, and performance.

More Than Diaphragms – Full Sealing and Motion Solutions

Alongside diaphragms, we design and manufacture:

- PTFE and polymer bellows

- Envelope and machined gaskets

- Lip seals, O-rings, and valve seats

- Chevron sets and expansion joints

Our sealing products are designed to protect processes, extend equipment life, and reduce maintenance costs, especially in corrosive and high-pressure environments.

Frequently Asked Questions

Yes. We manufacture diaphragms from FDA-approved and hygienic-grade PTFE, ideal for pharmaceutical and food contact applications.

Absolutely. We can reverse engineer from a worn or obsolete part to produce a direct replacement or an upgraded version.

Yes. We can incorporate metallic mesh, elastomer layers, or hybrid materials for added structural integrity and strength.