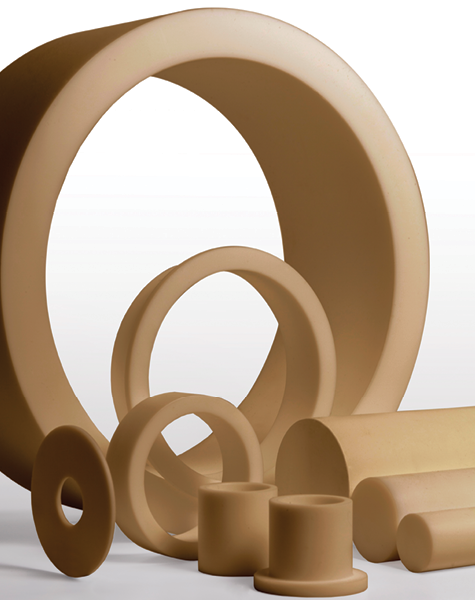

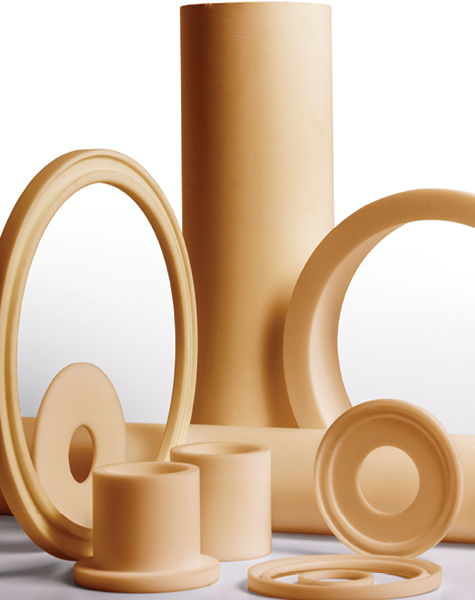

Cup Seals

Piston cups provide a mechanical sealing surface on the edge of hydraulic and pneumatic piston heads, plungers, and rams. Piston cups can include a hole in the centre of the cup. PTFE cups act as a self-sealing solution.

Made in Britain

PTFE Cup Seals

Piston cups provide a mechanical sealing surface on the edge of hydraulic and pneumatic piston heads, plungers, and rams. Piston cups can include a hole in the centre of the cup. PTFE cups act as a self-sealing solution.

PTFE Cup Seals Advantages

✔ Able to withstand friction – PTFE has one of the lowest friction coefficients of any solid material.

✔ Able to withstand high pressure – This is part of what makes PTFE seals so valuable in applications with heavy-duty machineries, such as mining or agriculture.

✔ Chemically inert – The carbon-fluorine bonds in PTFE make it non-reactive, meaning it cannot be broken down from repeated exposure to chemicals.

✔ Water, oil and dirt repellent – The fact that PTFE is resistant to these common contaminants makes it an excellent component in seals.

✔ The seal does not require lubrication.

✔ Can be used with a variety of media – PTFE lip seals have successfully been used to seal in (or out, as the case may be) all types of media, including granules, synthetic lubricants, powders, steam, resins, heat transfer oils, chemical wastewater, foodstuffs, glue and more.

✔ Resistant to extreme temperatures – The lowest temperature PTFE seals can operate at is – 2000C and the highest temperature is 2600C! Can run at high RPMs.

Typical Industries

- ✔ Aerospace

- ✔ Automotive

- ✔ Marine

- ✔ Oil & Gas

Bespoke PTFE Cup Seal Designs

Beldam Crossley can create PTFE products to your specification, creating a product with the correct PTFE grade material that works best for your application.

Contact our team of design engineers with your requirements and see how we can help you.

Beldam Crossley has been moulding PTFE for over half a century. We have since developed a wide range of High Performance Crossflon® materials, each suited to a specific application.

PTFE Cup Seals Advantages

Able to withstand friction

PTFE has one of the lowest friction coefficients of any solid material.

Chemically inert

The carbon-fluorine bonds in PTFE make it non-reactive, meaning it cannot be broken down from repeated exposure to chemicals.

Water, oil and dirt repellent

The fact that PTFE is resistant to these common contaminants makes it an excellent component in seals.

The seal does not require lubrication

Able to withstand high pressure

This is part of what makes PTFE seals so valuable in applications with heavy-duty machineries, such as mining or agriculture.

Can be used with a variety of media

PTFE lip seals have successfully been used to seal in (or out, as the case may be) all types of media, including granules, synthetic lubricants, powders, steam, resins, heat transfer oils, chemical wastewater, foodstuffs, glue and more.

Resistant to extreme temperatures

The lowest temperature PTFE seals can operate at is – 2000C and the highest temperature is 2600C! Can run at high RPMs.