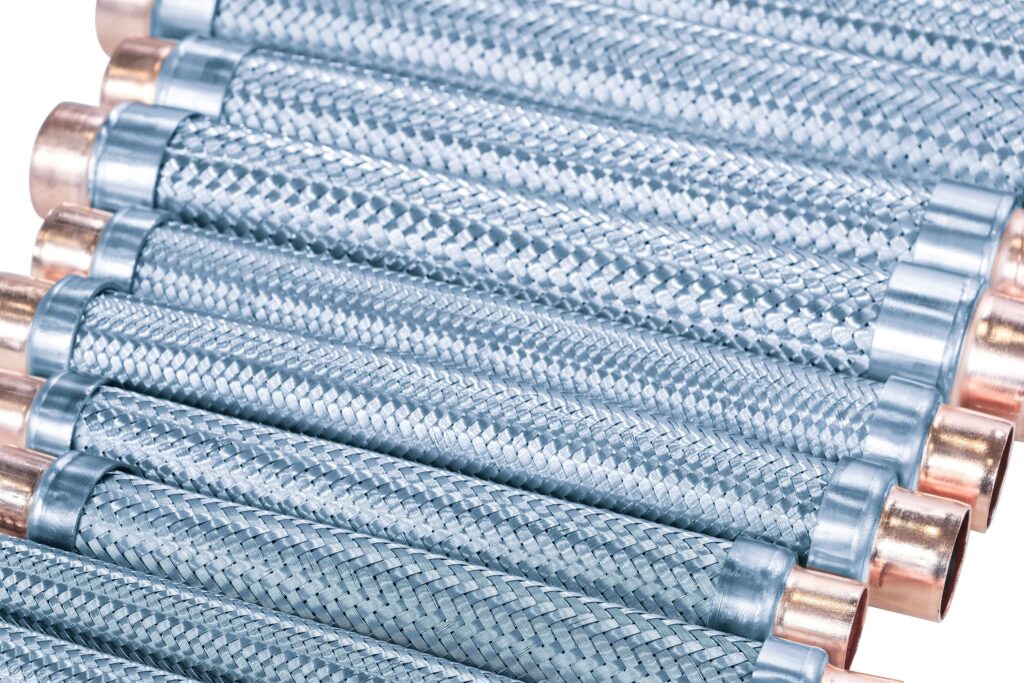

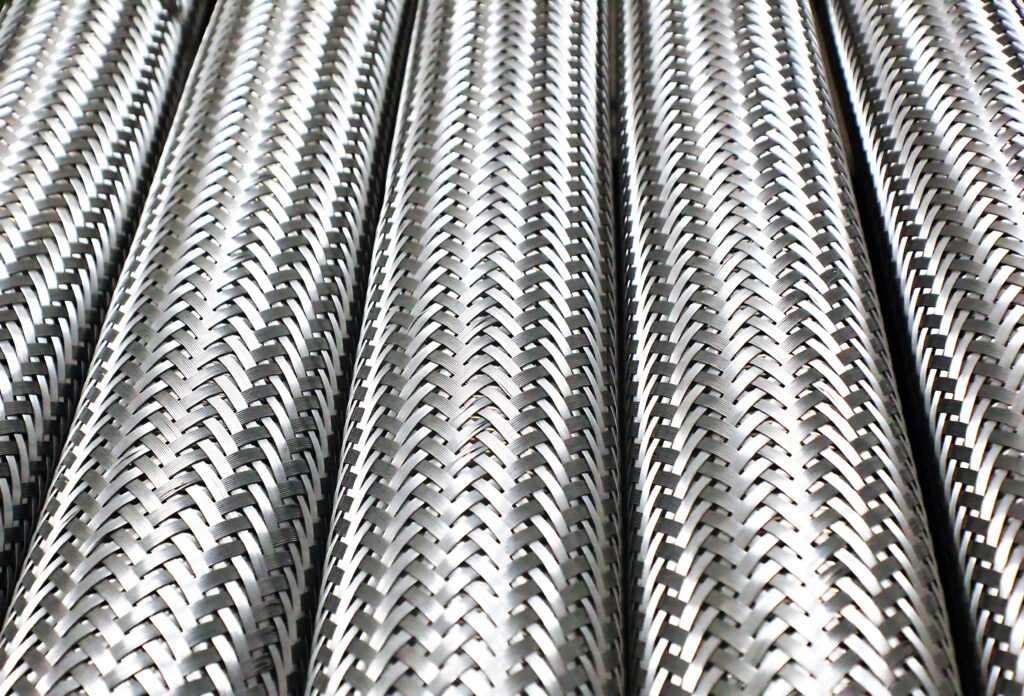

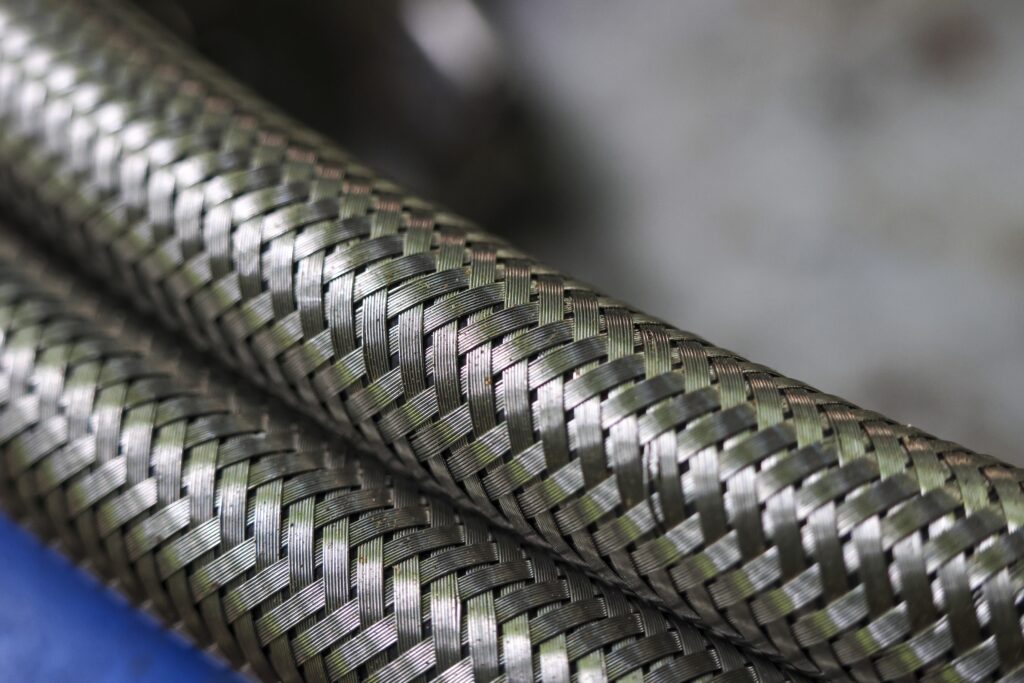

Wire and Textile Overbraid

Protection You Can Count On – Precision-Braided in the UK

Made in Britain

Protection You Can Count On – Precision-Braided in the UK

At Beldam Crossley, we understand that when your equipment is out in the field—whether it’s out at sea, deep underground, or moving at speed—it needs to perform without compromise. That’s why we design and manufacture high-quality wire and textile overbraid to shield your components, extend service life, and keep your operations running safely.

Our overbraid products are all made right here in the UK, backed by 149 years of engineering know-how and trusted across industries where durability, flexibility, and protection really matter.

What Does Overbraid Do?

Think of overbraid as tough, woven armour for your components. Whether it’s a stainless steel wire or a specialist textile yarn, this outer layer protects hoses, bellows, cables, and pipework from:

- Abrasion

- Heat

- Chemicals

- Mechanical stress

- Electromagnetic interference (EMI)

But it’s not just about protection. Our overbraid also enhances performance—especially when used on PTFE or metallic bellows, where it increases hoop strength and limits axial movement, helping to prevent over-extension and fatigue.

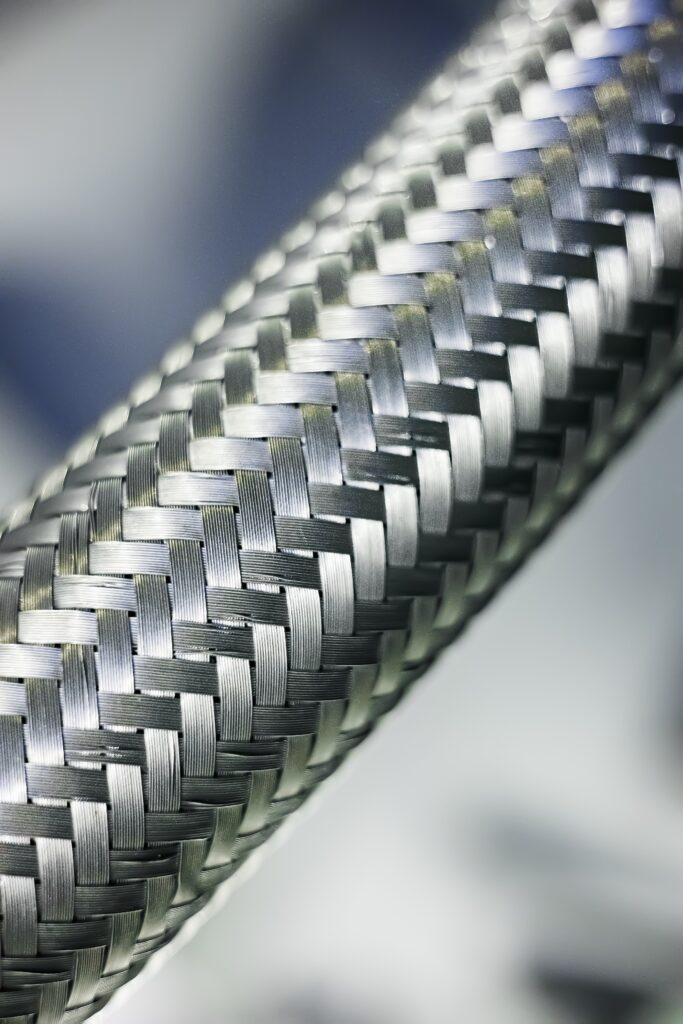

Braiding Materials We Offer

Every application is different. That’s why we offer a wide range of braiding materials to match your exact needs:

- Stainless Steel Wire (304 & 316) – For heavy-duty environments, marine systems, and subsea assemblies.

- Tinned Copper Wire – Ideal for EMI/RFI shielding in control systems and aerospace wiring.

- Kevlar® Yarn – Lightweight, ultra-strong, and perfect for demanding defence or motorsport applications.

- Nomex® Yarn – Flame-resistant and built for high-temperature zones like turbines and power plants.

- Polyester or Nylon Yarn – Flexible and cost-effective for everyday industrial use.

Need something unique? No problem—we can tailor the braid density, coverage, and diameter to suit your build.

Where You’ll Find Our Overbraid in Action

You’ll find Beldam Crossley’s wire and textile overbraid solutions across a huge range of industries, including:

- Aerospace – Protecting hydraulic lines and wiring looms from EMI and vibration.

- Subsea and Marine – Reinforcing connectors and bellows with corrosion-resistant metal braid.

- Rail & Transport – Textile overbraid used to guard flexible joints and reduce wear over time.

- Oil & Gas – Braided protection for hoses carrying high-pressure or aggressive media.

- Food & Pharma – Clean, fibre-shedding-resistant textiles for sanitary PTFE assemblies.

- Power Generation – Nomex®-braided bellows that handle intense heat and stress.

Our braids are commonly used to reinforce PTFE-lined hoses and bellows, adding both strength and safety in dynamic systems.

Why Engineers Trust Us

✔ Made in Britain, with full traceability and in-house control

✔ Customisable for your project’s exact demands

✔ Backed by a century of manufacturing expertise

✔ Trusted globally by OEMs and industry leaders

From one-off prototypes to high-volume runs, we’re ready to support your design, build, or retrofit needs—whatever the scale.

Speak To One Of Our Experts Today

Made in Britain. Built for the Toughest Aerospace & Defence Environments

When equipment needs to survive extreme conditions, reliability becomes non-negotiable. Beldam Crossley manufactures wire and textile overbraid in the UK to protect hoses, bellows, cables and pipework in environments where failure simply cannot occur. From high-altitude aerospace systems to defence vehicles and missile platforms, our braid is designed to perform when the stakes are highest.

With almost 150 years of engineering heritage, we are one of the last remaining UK manufacturers of custom overbraid. OEMs and tier suppliers choose Beldam Crossley because the product doesn’t just meet specification — it consistently performs in the field.

High-Performance Protection

Our overbraid provides robust mechanical, chemical and thermal defence where standard hose or cable insulation would degrade. It resists abrasion, vibration, fluid ingress, chemicals and environmental exposure while maintaining stability in high-temperature and fire-risk zones. On electronic platforms, metallic overbraid also helps protect signal integrity by reducing electromagnetic and radio-frequency interference.

Where It’s Used — Key Applications

- Hydraulic hose assemblies and PTFE bellows on aerospace and defence platforms

- High-temperature engine, turbine and actuator systems in aircraft and power generation

- EMI-shielded cable looms for avionics, communications and mission-critical electronics

- Subsea connectors and marine assemblies requiring protection from corrosion and movement

- Washdown-safe PTFE hoses for food, beverage, pharmaceutical and medical environments

Industries We Support

Aerospace and defence remain the primary focus of our overbraid manufacturing, where the highest levels of performance, traceability and compliance are demanded.

Alongside these sectors, the same durability and reliability benefits make Beldam Crossley overbraid a trusted solution across a wide range of industrial environments, including:

- Oil & Gas — onshore and offshore

- Subsea and marine assemblies

- Power generation and turbine systems

- Industrial machinery and factory automation

- Rail, heavy transport and commercial vehicle platforms

- Motorsport — high-temperature and high-vibration systems

- HVAC and refrigeration equipment

- Chemical processing and chemical-transfer systems

- Food and beverage production environments

- Pharmaceutical and medical equipment

- Fire safety and emergency response systems

Wherever critical assemblies are exposed to abrasion, movement, heat, vibration, contamination or aggressive cleaning regimes, our overbraid is already in service.

Engineered to Your Requirements

Every programme is different, and each overbraid is designed around the operating conditions it must survive. We work directly with design teams to select and optimise the braid material, coverage density and pattern for the environment — whether the priority is fire-survival capability, EMI shielding, chemical stability, reduced weight for aerospace, or heavy-duty abrasion resistance for defence vehicles and subsea equipment.

Why Beldam Crossley

All braid is manufactured in the UK at our facility in the North of England, ensuring full traceability and tightly controlled quality from raw material through to finished product. For regulated sectors, we hold AS9100 aerospace accreditation alongside ISO 9001 and JOSCAR approval, making supplier onboarding and programme qualification straightforward for aerospace and defence primes and their supply chains.

Investment in machinery and stockholding gives us some of the fastest lead times in the UK market, supporting rapid prototypes, small-batch runs and full-scale production schedules. Because we manufacture both the braid and the engineered assemblies it protects, we apply real-world performance experience rather than theoretical assumptions. We support both new product development and legacy upgrades, including failure analysis and redesign where reliability improvements are required.

Let’s Talk About Your Project

Our engineering team can review your specifications, drawings or samples and provide recommendations quickly. We can assist with qualification testing and help optimise solutions for performance, cost and long-term reliability.

Frequently Asked Questions

Great question. The overbraid doesn’t just protect—it also adds hoop strength to the tubing, reducing risk of ballooning or stretching. It helps control axial movement and extends the service life of the entire system.

Absolutely. You can specify material, coverage density, braid angle, and diameter. We’ll work with you to make sure it’s exactly right for your operating environment.

Yes. We offer clean, non-shedding textile options suitable for food processing and pharmaceutical environments—often paired with FDA-approved PTFE components.