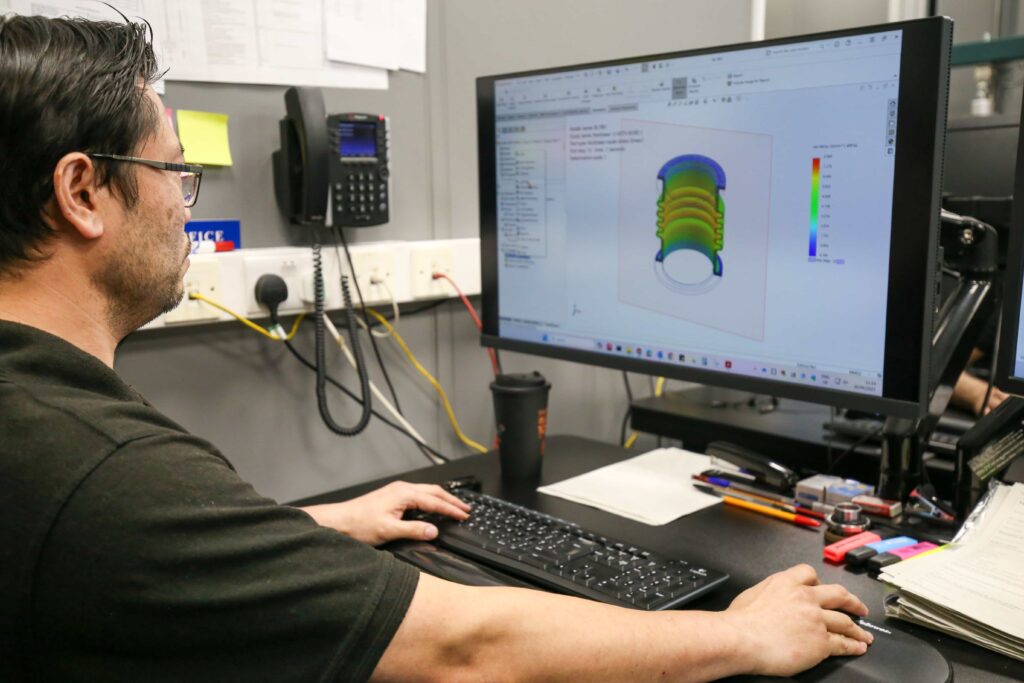

At Beldam Crossley, we go beyond supply — we collaborate from the ground up. Our team works alongside OEM design engineers, project managers, and procurement specialists to develop bespoke seal and bearing solutions that meet the most demanding technical, environmental, and regulatory requirements.

Whether you’re in early-stage prototyping or full-scale production, we ensure:

- Material compatibility for extreme environments

- Precision manufacturing for tight tolerances and complex geometries

- In-house testing to validate performance under real-world conditions

- Compliance with international standards across defence, aerospace, marine, transport and energy