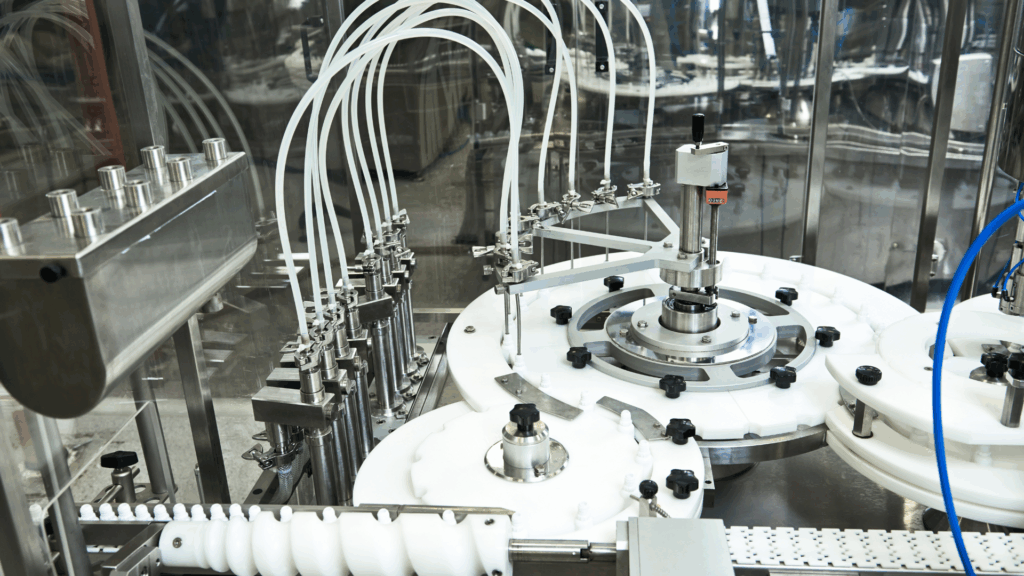

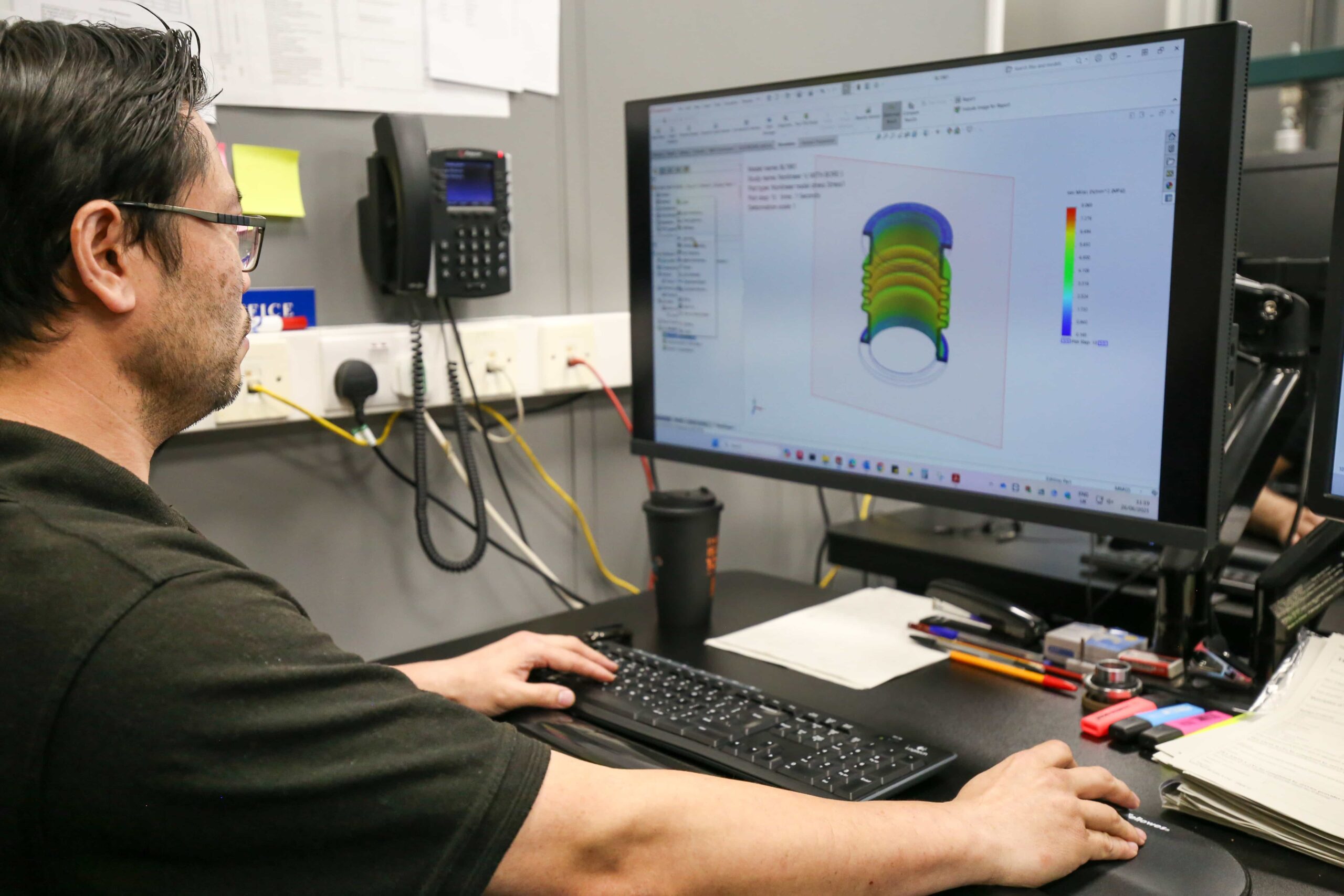

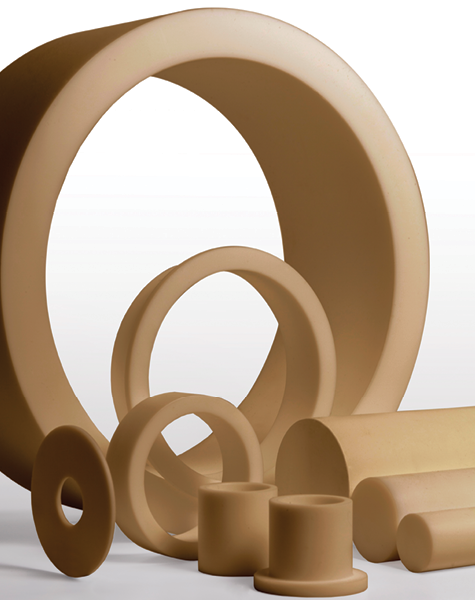

At Beldam Crossley, we manufacture precision-engineered PTFE and polymer components for the medical device and pharmaceutical manufacturing industries. Our solutions range from bespoke seals for OEM medical equipment to chemically resistant gaskets and diaphragms for pharmaceutical processing systems.

Backed by over 100 years of engineering expertise, we support both standard and custom component requirements—manufactured in the UK to the highest global standards.