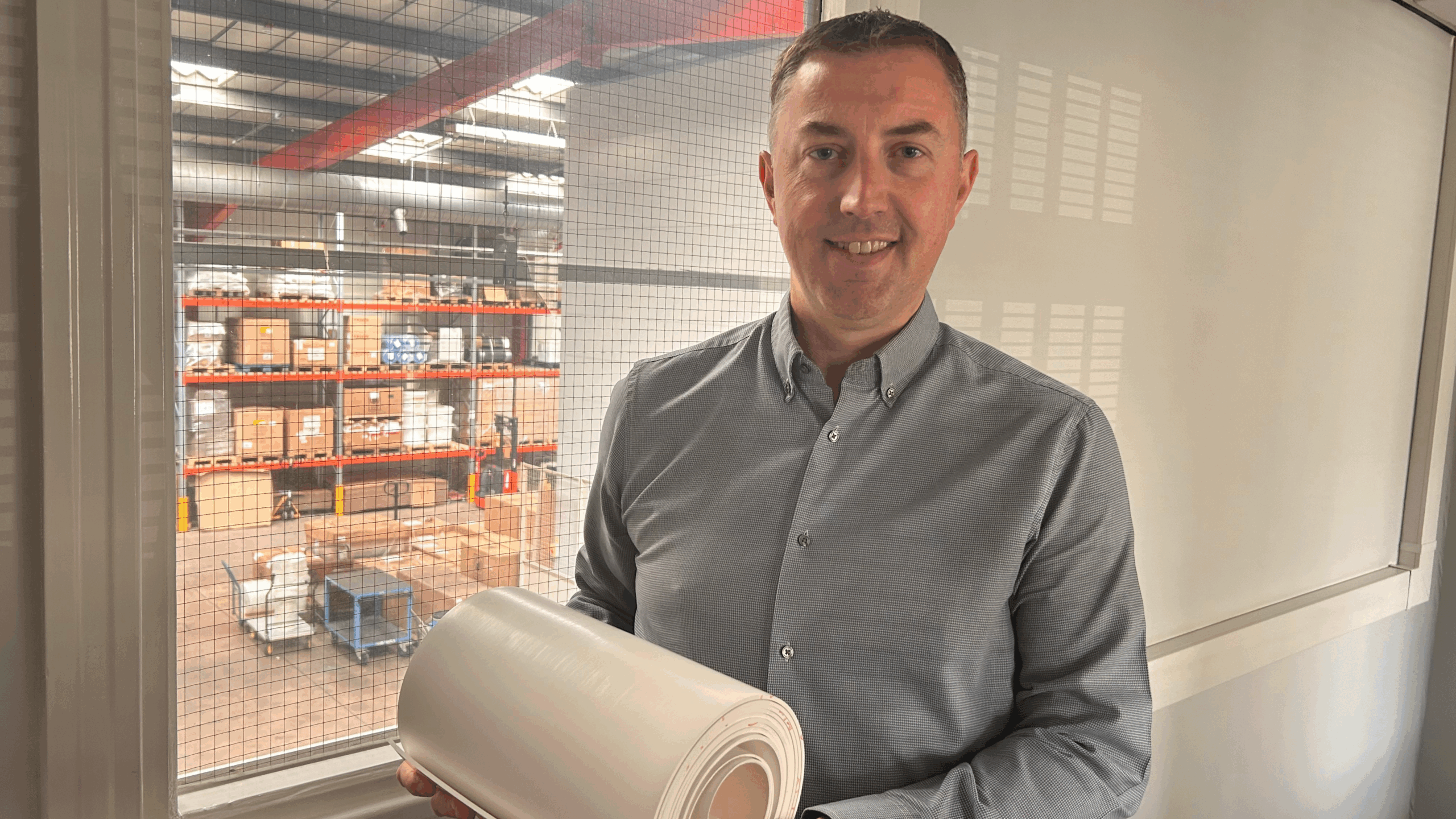

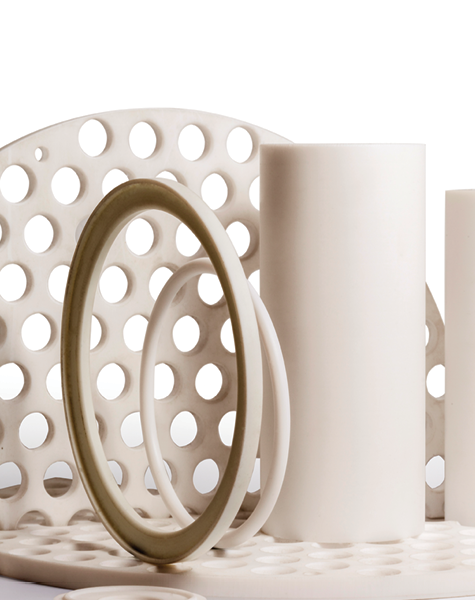

Beldam Crossley is a leading UK manufacturer of PTFE and precision polymer components engineered for use in food and beverage processing environments. From bespoke parts for OEM food equipment to durable sealing systems in hygienic manufacturing lines, our components help producers maintain the highest standards of cleanliness, performance, and compliance.

With over 100 years of industrial expertise and modern UK-based manufacturing, we supply food-safe, chemically inert solutions built to withstand the challenges of food contact and sanitation.