Interview: Inside the Rise of Beldam Crossley’s Skidway Systems

How engineering precision, material science and global collaboration are redefining offshore loadout performance.

When you sit down with Ian Harbottle, Divisional Manager at Beldam Crossley, you quickly realise that “skidway systems” are far more than just steel beams and bearing plates. They’re the unseen backbone of some of the world’s most ambitious offshore construction projects — systems that quietly carry tens of thousands of tonnes of engineered structures from shore to sea.

When you sit down with Ian Harbottle, Divisional Manager at Beldam Crossley, you quickly realise that “skidway systems” are far more than just steel beams and bearing plates. They’re the unseen backbone of some of the world’s most ambitious offshore construction projects — systems that quietly carry tens of thousands of tonnes of engineered structures from shore to sea.

“If we’re not the global leader in this product,” Ian begins, “we’re certainly one of them. We can logistically make that claim. Our products have been used to skid some of the world’s biggest offshore structures ever built.”

From Bolton to the Global Stage

Beldam Crossley has been manufacturing skidway systems for more than two decades, supplying fabrication yards and barge operators worldwide. But 2024 marked a milestone.

“Last year was our record year,” Ian explains. “Some of the world’s largest topsides and jackets were skidded using our technology. It’s been an incredible period of growth — we’ve not only broken the £1 million turnover mark for skidways and bearings, but we’ve also expanded our customer base into new regions.”

That growth, he notes, came on the back of both recovery and renewal. “There was a natural dip during COVID, as major fabrication projects were paused. What followed was a surge — yards catching up, and operators looking for proven, reliable systems. It’s been a case of experience meeting opportunity.”

Engineering the Movement

At the heart of every skidway system is Crossflon® XF225, a proprietary PTFE-based bearing material that Beldam Crossley bonds to steel backing plates to create ultra-low-friction tracks. These are then welded to skid beams, forming the base on which entire offshore structures slide during loadout or launch.

“In simple terms,” Ian says, “our material forms the low-friction interface between the structure and the beam. It has extremely low friction values, it’s hard-wearing, weather-resistant, and it will take very high loads. In my view, it’s the best product of its type in the market.”

The technology has been tested not just in laboratories but in the toughest environments on earth.

“We always say lab testing gives you the theory, but real-world data gives you the truth,” Ian adds. “When our customers carry out a loadout, they record the pulling forces used to move these huge structures. From that, you can calculate friction. And those figures prove what we already know — that our specified values are achievable in real conditions.”

Defining Offshore Scale

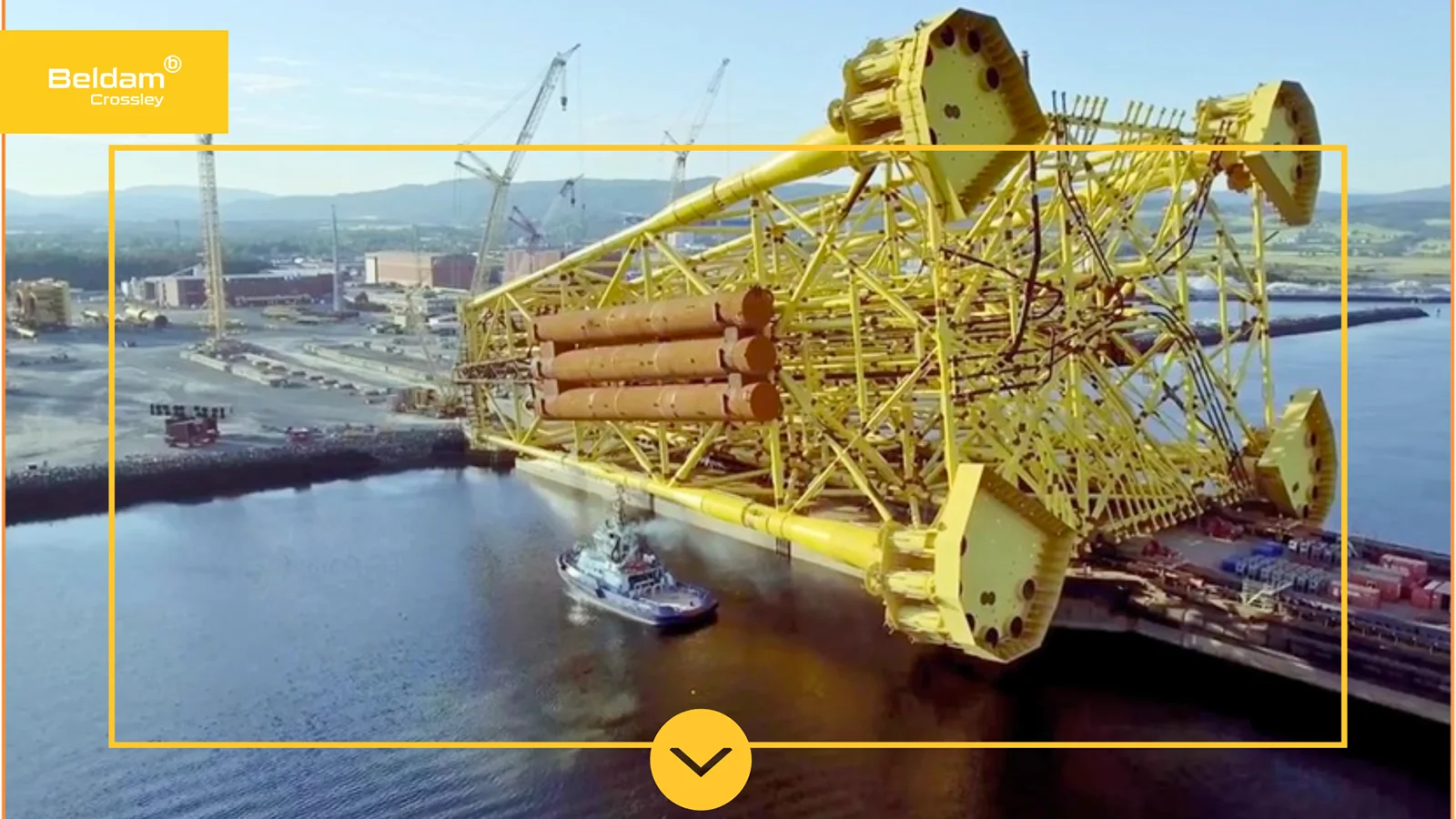

To appreciate the scale of the challenge, Ian describes one of the projects in which Beldam Crossley’s systems played a part.

“That particular topside weighed nearly 48,000 tonnes (Including the deck support frame) — to my knowledge, the largest ever skidded in the history of the world. I doubt it’ll ever get much bigger than that.”

Projects like this demand a level of precision that goes far beyond basic manufacturing. Each plate must maintain dimensional stability under extreme pressure, resist environmental degradation, and perform reliably whether in the searing heat of the Middle East or the humidity of Southeast Asia.

“You can’t afford inconsistencies,” Ian notes. “If one section grips harder than another, it can throw off the entire load-out. That’s why our customers trust us — the consistency of the product, the traceability, the testing — it all counts.”

Breaking New Ground

Beldam Crossley’s skidway technology has supported projects in the Middle East, Europe, Mexico, Malaysia, and China, with major yards now switching to their systems over traditional alternatives.

“We even gained a new customer last year who had always gone to our biggest competitor. That was a big step forward — proof that performance speaks louder than price.”

The company’s approach blends material science with hands-on engineering collaboration. Each system is tailored to suit its project’s geometry, loading and operational conditions.

“Every yard and every vessel has a slightly different setup,” Ian explains. “We don’t just sell a plate — we work with engineers to make sure the interface is right, the tolerances are right, and that the whole system performs as one.”

The Challenge of Sourcing the Right System

Ask Ian what the biggest challenge is for clients sourcing a skidway, and his answer is immediate:

“Integration. Getting every part — the beams, plates, and bearings — to work together under real-world conditions. The materials must carry extreme loads and maintain low friction, but they also have to be consistent, certified, and ready when the project needs them. That’s not something you can buy off the shelf.”

With in-house design, material blending, machining, and testing all under one roof in Bolton, Beldam Crossley has positioned itself as a true engineering partner — not just a supplier.

“That’s what makes the difference,” Ian concludes. “When you control the process from raw polymer to finished skidway system, you control performance, reliability, and delivery. That’s what our customers depend on.”

About Beldam Crossley

Founded in 1876 and part of the Indutrade Group, Beldam Crossley specialises in engineered sealing, bearing and polymer solutions. Its Crossflon® range of advanced PTFE-based materials are used in critical applications across marine, subsea, aerospace, and energy sectors worldwide.