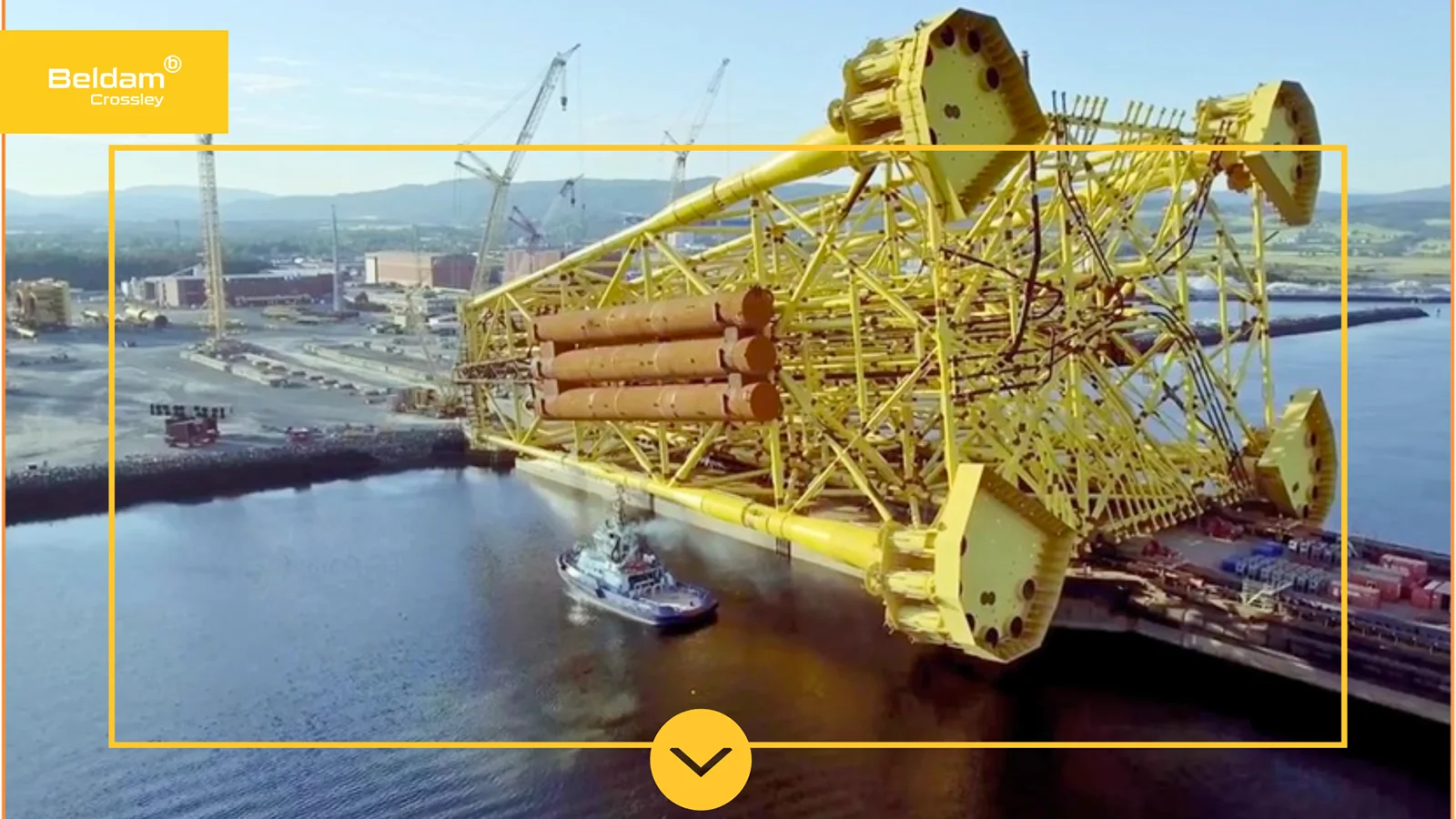

Beldam Crossley introduces a high-load, ultra-low-friction PTFE compound engineered for the demands of SURF systems, subsea structures, and offshore bearing assemblies.

In the harsh and unpredictable conditions of offshore and subsea environments, materials face relentless mechanical stress, fluctuating temperatures, and exposure to demanding operating cycles. Bearings, pads, and sliding components in SURF hardware, pipeline end terminations (PLETs), riser systems, and subsea modules are expected to perform without failure—often in constrained spaces, under enormous load, and with minimal opportunity for maintenance.

Historically, PTFE has been the go-to for low-friction performance, but it has always come with mechanical limitations. Its inability to handle sustained compressive loads without deformation meant engineers were forced to add mechanical reinforcements, overbuild surrounding structures, or shift to costly composite alternatives. These compromises added weight, complexity, and time.

Crossflon® XS, developed by Beldam Crossley, directly addresses this problem. It’s a new class of reinforced PTFE—engineered from the ground up for structural stability and dimensional integrity under stress. What distinguishes Crossflon® XS is its ability to retain the frictional benefits of PTFE while dramatically expanding the material’s pressure-bearing capabilities. It withstands compressive pressures up to 32 MPa in non-recessed designs, and up to 75 MPa when recessed—a significant leap beyond traditional filled PTFE materials.

This extended performance envelope allows design engineers to reduce bearing sizes, eliminate steel recesses in some configurations, and simplify assemblies without sacrificing safety margins. Under ASTM D695 testing, Crossflon® XS reaches 51 MPa at 5% compressive strain, and maintains structural shape with less than 1% deformation after 24 hours at 14 MPa. It continues to perform across an extreme temperature range from –250°C to +260°C, making it ideal for both deep-sea cold conditions and high-temperature topside equipment.

Friction performance is equally impressive. Crossflon® XS delivers a static coefficient of friction between 0.03 and 0.06, enabling smoother load transitions and eliminating stick-slip in linear bearing applications. It also resists water absorption (less than 0.01%) and is self-extinguishing when tested to ASTM D635, supporting material integrity in wet and fire-critical offshore zones.

Unlike many other materials used in subsea applications, Crossflon® XS is manufactured entirely under one roof in the UK. Beldam Crossley controls every aspect of the process—from blending to machining—ensuring complete traceability, batch consistency, and rapid response to QA audits. For offshore operators and EPCs working within strict compliance frameworks, this is more than a convenience—it’s a risk reducer.

The applications are wide-ranging. Crossflon® XS is suitable for use in subsea bearing blocks, modular skid assemblies, flowline deployment systems, and structural guides in motion-critical areas. It also allows rethinking of design standards in high-pressure interfaces, especially where previous PTFE grades would have been ruled out.

“Crossflon® XS gives engineers freedom they didn’t have before,” said Ian Harbottle, Divisional Manager at Beldam Crossley. “We’re not talking about marginal gains. This is a material that moves PTFE into applications where it was never viable. You can design with confidence, reduce component count, and deliver performance at a level previously reserved for specialist composites.”

“Crossflon® XS gives engineers freedom they didn’t have before,” said Ian Harbottle, Divisional Manager at Beldam Crossley. “We’re not talking about marginal gains. This is a material that moves PTFE into applications where it was never viable. You can design with confidence, reduce component count, and deliver performance at a level previously reserved for specialist composites.”

With Crossflon® XS, Beldam Crossley is pushing the boundaries of polymer engineering to meet the real-world demands of subsea infrastructure—bringing strength, simplicity, and British manufacturing to the heart of offshore energy systems.

About Beldam Crossley

Beldam Crossley is a UK-based manufacturer of high-performance sealing and bearing systems. Serving industries including offshore energy, nuclear, aerospace, and defence, the company develops proprietary material technologies backed by full in-house production capabilities and over a century of engineering excellence.