The Benchmark in Custom Polymer Solutions Precision-Engineered in the UK. Trusted Worldwide.

Made in Britain

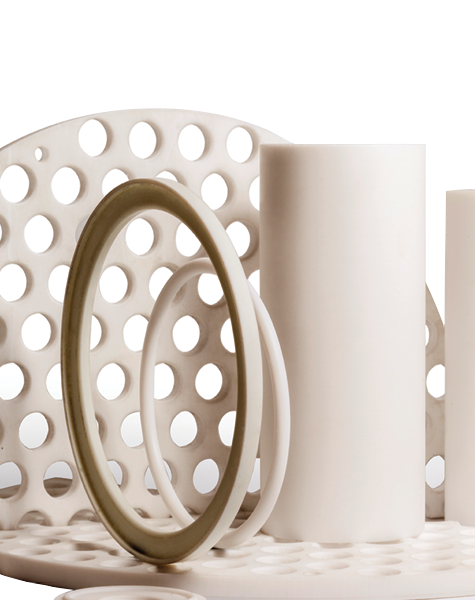

Crossflon® is Beldam Crossley’s proprietary range of high-performance PTFE and filled polymer materials, engineered to deliver superior sealing, bearing, and insulation performance across the most demanding industrial environments.

From pharmaceutical production lines to offshore tankers and clean-in-place food systems, Crossflon® components are relied upon where chemical resistance, hygiene, and mechanical strength are critical—and where off-the-shelf polymers simply don’t go far enough.

Unlike mass-market polymer brands, Crossflon® is not a single product—it’s a full range of advanced material grades, each developed to address specific engineering challenges. The difference lies in our ability to collaborate directly with our customers, tailoring material blends, component design, and performance characteristics for optimal results.

Crossflon® materials are based on high-grade PTFE (Polytetrafluoroethylene), enhanced with advanced fillers such as glass, bronze, carbon, graphite, and proprietary compounds. These fillers are chosen and blended by our in-house engineers to modify the base PTFE and achieve:

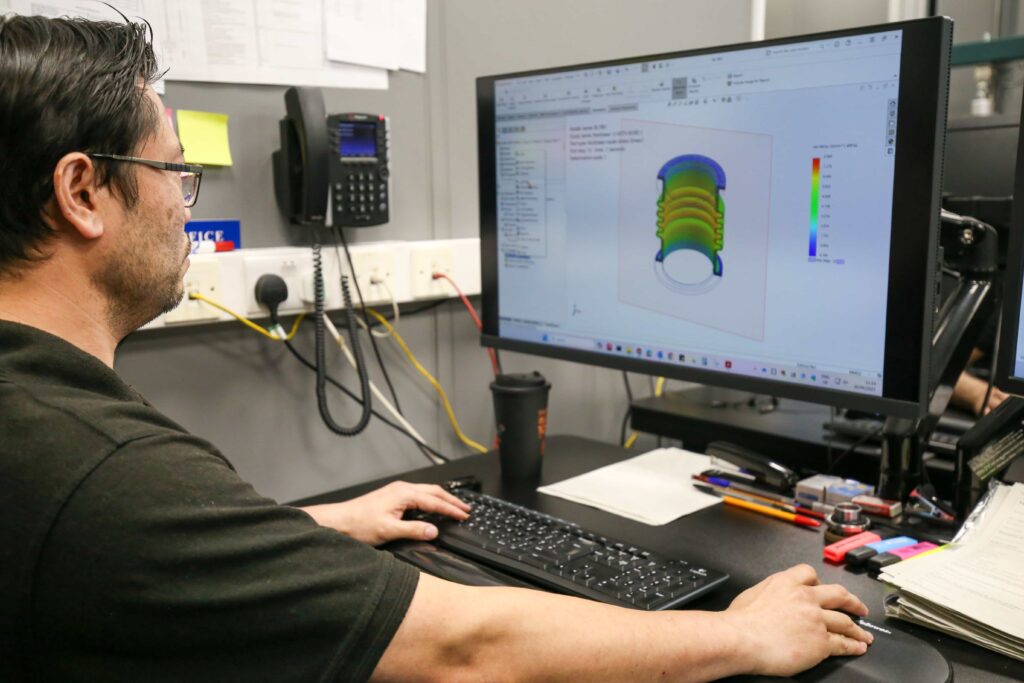

At Beldam Crossley, we don’t just sell material—we deliver custom-engineered polymer solutions. Our end-to-end UK manufacturing capabilities allow us to work alongside your engineering or procurement team at every stage:

This integrated process enables us to produce bespoke gaskets, seals, valve seats, bellows, diaphragms, clamp fittings and more, all made to suit your unique specifications, not someone else’s template.

Many suppliers offer “standard” PTFE parts or basic filled grades—usually manufactured abroad with limited quality control and even less application input. These materials often suffer from:

By contrast, Crossflon® products are designed, tested, and manufactured entirely in the UK, with full traceability and ISO 9001 / AS9100 quality compliance.

Crossflon® polymer components are trusted by global OEMs, plant operators, and engineers across:

Wherever reliability, hygiene, or performance matters—Crossflon® delivers.

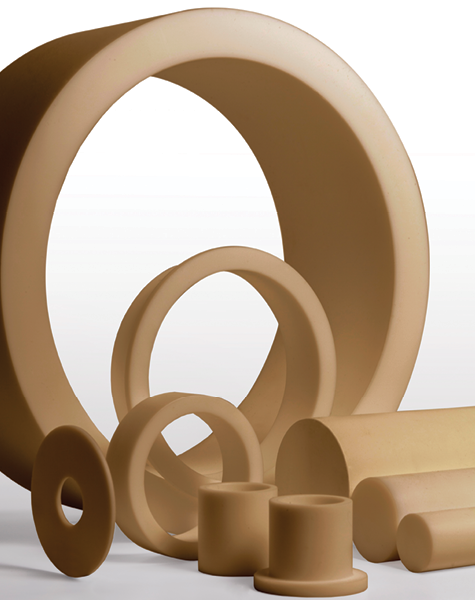

Typical Crossflon® components include:

We also manufacture to your design—bringing your ideas into production quickly, accurately, and cost-effectively.

Looking for a partner who understands your application, not just a supplier with stock?

Beldam Crossley’s Crossflon® brand offers more than materials—it offers trust, performance, and engineering expertise.

PTFE Bellows

Beldam Crossley offers a comprehensive PTFE bellow design and manufacturing service. They are used in many applications and prove effective in reducing vibration transmission, whilst accommodating expansion and contraction in various equipment.

Bearings & Bushes

Providing a range of high quality, UK manufactured Crossflon® Bearings and Bushes. Our range help to combat issues such as poor lubrication, excessive heat and friction water and corrosion issues found with other bearings and bushes.

Lip Seals

Beldam Crossley provides a range of PTFE Lip Seals designed to withstand aggressive environments in the use of rotary applications and equipment, helping to bridge the gap between current technologies for both gas and liquid sealing applications.

Piston Rings

Beldam Crossley PTFE piston rings are manufactured and have been used in oil-free compressors for years. There has been an increase in demand in recent years, with an emphasis on environmental benefits and further cost reduction methods and materials which PTFE Piston rings help to achieve.

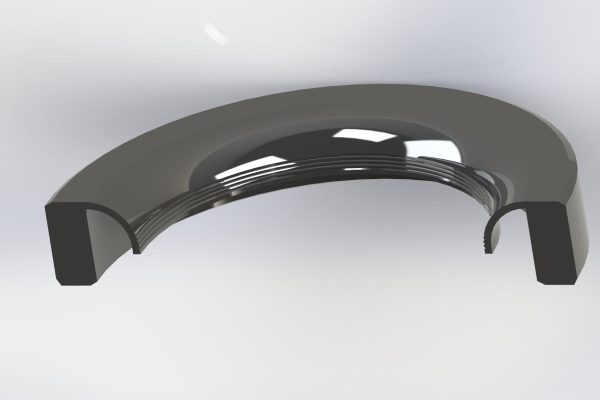

Cup Seals

Our cup seals offer a mechanical sealing surface on the edge of hydraulic and pneumatic piston heads, plungers and rams that are useful in applications that have large extrusion gaps, typically lower pressure applications. PTFE Piston cups can include a hole in the centre of the cup and can act as a self-sealing solution.

PTFE / Teflon Seals

Beldam Crossley provides a bespoke PTFE / Teflon seal design facility, providing you with the exact product that matches your specification. We work with multiple grades of PTFE and without experience and expertise can provide an effective, efficient solution to your sealing requirements.

1000

Non absorbing material, particularly suited to bearing applications.

1110

Inert to most chemicals and is well suited for use in seals exposed to elevated temperatures, high loads or steam contact.

1403

Reinforced PTFE material providing a good balance of mechanical and tribological characteristics.

1601

Excellent deformation under load. Good weldability and good resistance to weather and ultra violet exposure.

| --- | 400 series (403, 405, 407) |

500 series (505, 508, 512) |

600 series (601, 603, 605, 608) |

700 series (702, 703, 705, 707) |

900 series (905, 910) |

1400 series (1402, 1403, 1408) |

1800 series | LR series (LRD4, LRD5) |

J series | FG series | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property | Units | Test method | UNFILLED PTFE | CROSSFLON 403 | CROSSFLON 512 | CROSSFLON 605 | CROSSFLON 705 | CROSSFLON 905 | CROSSFLON 1403 | CROSSFLON 1801 | CROSSFLON LR (D5) | CROSSFLON J | CROSSFLON FG |

| General composition | --- | --- | Ptfe | Ptfe Graphite | Ptfe Bronze | Ptfe Glass | Ptfe Carbon/Graph | Proprietary Grade | Proprietary Grade | Proprietary Grade | Proprietary Grade | Proprietary Grade | Proprietary Grade |

| Operating temperature | °C | --- | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 | -250 to +260 |

| Specific gravity | g/cm3 | ASTM D1457 | 2.19 | 2.15 | 3.86 | 2.25 | 2.08 | 2.32 | 2.06 | 2.12 | 2.27 | 1.81 | 2.25 |

| Hardness | Shore 'D' | ASTM D2240 | 58 | 62 | 70 | 65 | 60 | 62 | 62 | 56 | 62 | 60 | 60 |

| Tensile strength | MPa | ASTM D1457 | 25 - 30 | 14 - 18 | 16 - 20 | 18 - 22 | 18 - 22 | 16 - 22 | 20 - 26 | 25 - 30 | 16 - 20 | 16 - 22 | 24 - 30 |

| Short term limiting PV @ .05m/s | MPa m/s | BCL method | 0.065 | 0.42 | 0.78 | 0.45 | 0.7 | 0.78 | 0.9 | 0.1 | 0.7 | 0.26 | 0.35 |

| Maximum (P) | MPa | BCL method | 6.9 | 14 | 14 | 14 | 14 | 14 | 20 | 7 | 14 | 5.2 | 6.9 |

| Maximum (V) | m/s | BCL method | 1.3 | 5 | 2 | 2 | 5 | 5 | 5 | 2 | 2 | 2 | 2 |

| Coefficient of friction (dry) static @ 0.2 MPa | 0.04 | 0.09 | 0.11 | 0.1 | 0.1 | 0.08 | 0.09 | 0.07 | 0.13 | 0.12 | 0.1 | ||

| Dynamic @ 0.2 MPa 5m/s | 0.07 | 0.11 | 0.13 | 0.12 | 0.12 | 0.11 | 0.11 | 0.08 | 0.15 | 0.13 | 0.1 | ||

| Wear (K) factor vs 1040 steel – 12-16 RMS | mm3/Nm x 10-9 | BCL method | 6.6 | 0.9 | 4.2 | 2.3 | 1 | 0.3 | 0.21 | 3.2 | 2.2 | 1.5 | 0.81 |

| RECOMMENDED / TYPICAL APPLICATIONS | Gaskets, bearings, all bellows types, flange linings, seal rings | Bearings in wet and dry applications, piston rings, valve seats and plugs. Washers in contact with water. | Bearings, piston rings, valve seats and valve plugs. Preferred to general glass filled PTFE at high speed or against soft faces. | Bearings & bearing pads, piston rings, valve seats, & valve plugs, gaskets. | Bearings, seal rings, piston rings, valve plugs & compressor rings, gaskets, or apps involving HF or HF (AQ). | Bearings, seals and piston rings. Valve seats. Gaskets and bearings used in vacuum services. | Suitable for most applications that need low wear and/or high load bearing ability. | Gaskets, bearings, all bellows types, flange linings, seal rings. | Dry bearings & pads for general use, cup seals, M/C tool slideways and hydraulic piston rings. | Soft mating surfaces such as Brass, SS, and Al. Tape and std bearings for textile, auto, pkg, etc | Bearings, pads, seals, valve seats, etc, on food process machinery and vending m/c, etc. | ||

We have been innovators in our industry for over a century. Since 1876 we have a solid track record of providing industrial sealing & bearing technology that protects lives, investments and environments.