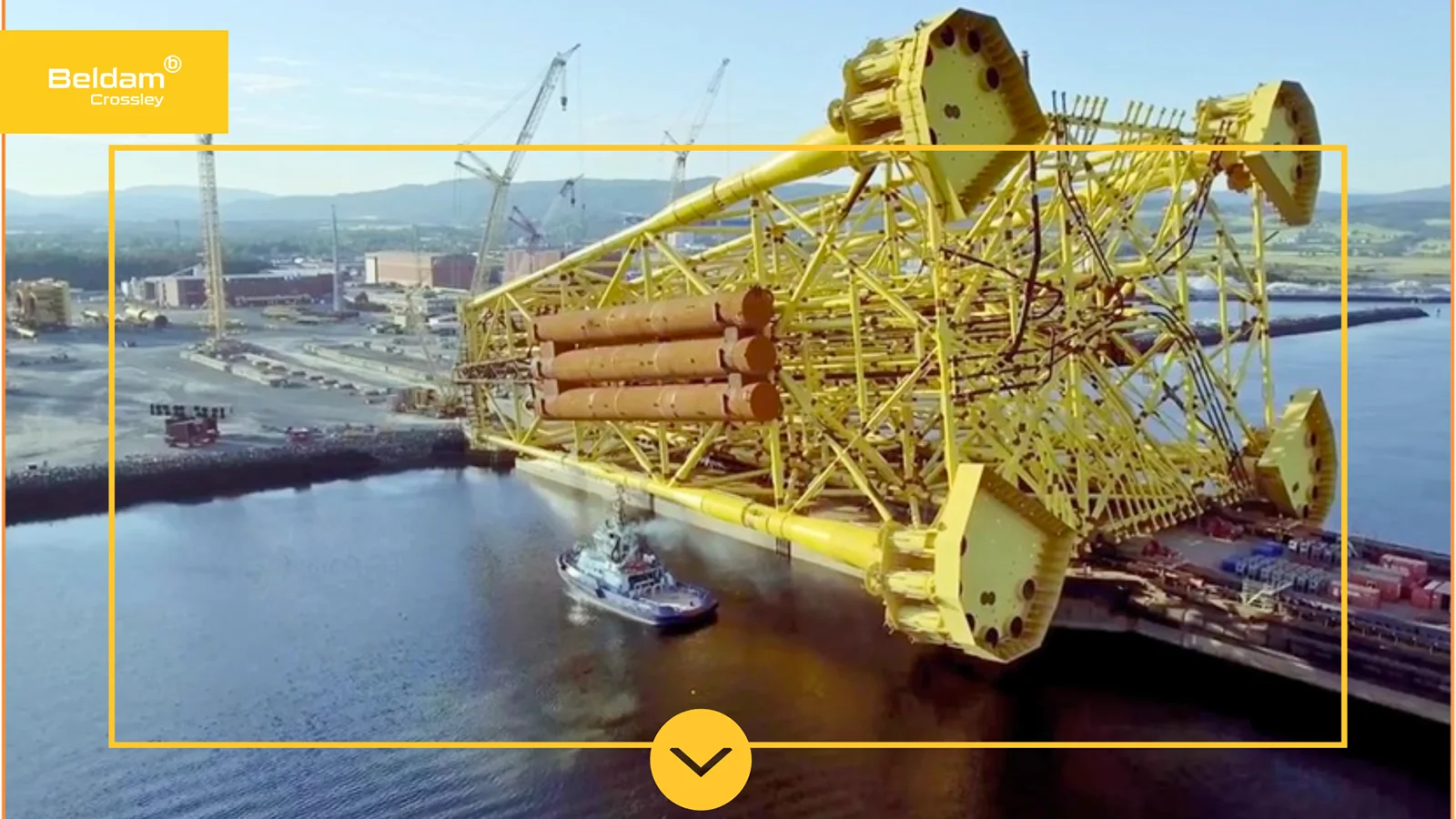

Bolton, UK – 12.6.25 – Beldam Crossley, a trusted UK manufacturer of precision-engineered sealing solutions for over 149 years, is proud to showcase the universal performance of its LidPack® hatch sealing range, now proving indispensable not only for marine vessels but also for road and rail tanker applications.

Originally developed for the demanding marine sector, the LidPack® range delivers superior durability, chemical resistance, and pressure integrity—characteristics that directly translate to improved performance and longevity for road and rail tankers. As the only UK’s manufacturer of DNV- and US Coast Guard-approved hatch seals, Beldam Crossley continues to lead in quality, innovation, and speed of service.

“Tanker owners are under pressure to reduce leaks, comply with international safety standards, and minimise downtime,” said Gareth Holt, Director at Beldam Crossley.

“Our LidPack® seals are helping customers move away from generic imports and invest in UK-made solutions designed to last and perform under critical conditions.”

Addressing Seal Failures and Downtime in Tanker Operations

Tanker operators across road, rail, and marine sectors are increasingly frustrated with imported low-grade value seal kits, particularly ball valve seats that arrive with long lead times and deteriorate during storage. These perishable seals not only threaten operational reliability but also put asset integrity at risk.

Beldam Crossley’s Ball Valve Seal Kits are engineered to eliminate these risks.

Made in the UK from high-grade PTFE blended with reinforcement materials such as glass, these seals are chemically inert, resistant to deformation with persistent usage, and built to withstand long storage periods without compromising performance. Designed to protect the investment in precision valves, each kit offers long-lasting integrity, improved flow control, and resistance to aggressive chemicals and extreme temperatures.

Customised Solutions for Demanding Environments

Beldam Crossley understands that sealing challenges are rarely one-size-fits-all. That’s why every ball valve seat or seal kit can be tailored to an existing specification or custom-designed for the unique needs of each application, including:

- Food-grade seals made with Titanium Dioxide for hygienic compliance

- WRAS-approved materials for potable water and water storage tanks

- Crossflon™ 1801 polymer blend, a non-static, anti-spark formula developed for flammable chemicals and fuels, helping operators comply with ATEX regulations and reduce explosion risks

All Built for Performance. Delivered with Speed.

Unlike overseas suppliers, Beldam Crossley maintains local control from their factory in Bolton over lead times, stock availability, and manufacturing processes. This agility allows them to deliver faster, with technical support and quality assurance baked into every batch.

With a legacy of protecting fleets and facilities for nearly a century and a half, Beldam Crossley continues to evolve with the needs of today’s fluid handling industry—offering UK-made, industry-certified sealing solutions that never compromise on safety, quality, or performance.

For more information, to place an enquiry, or request a custom seal design, visit