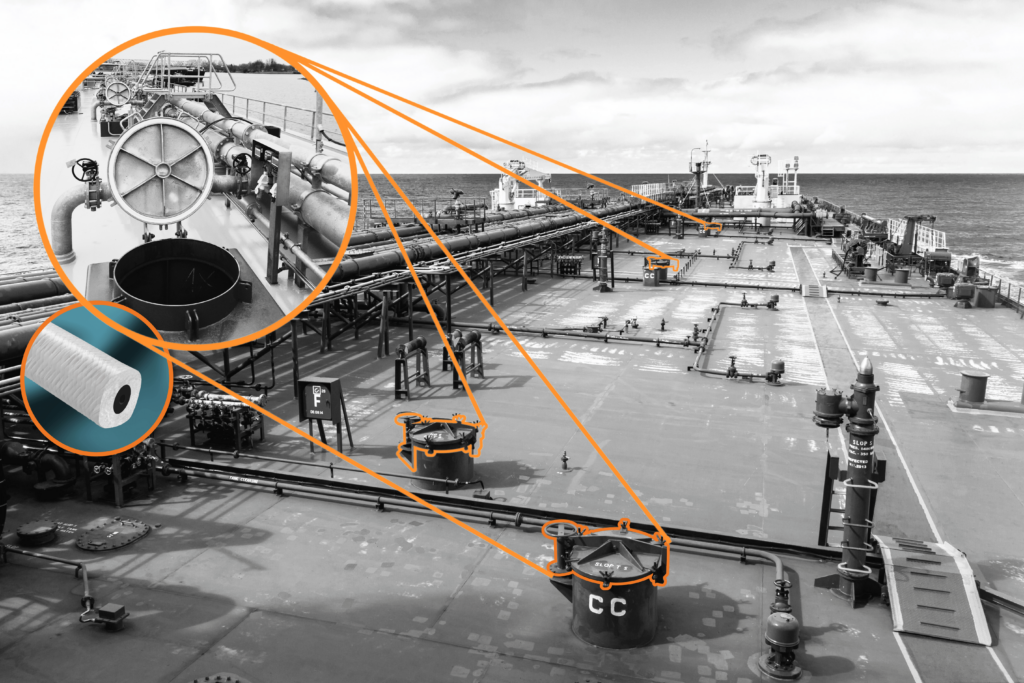

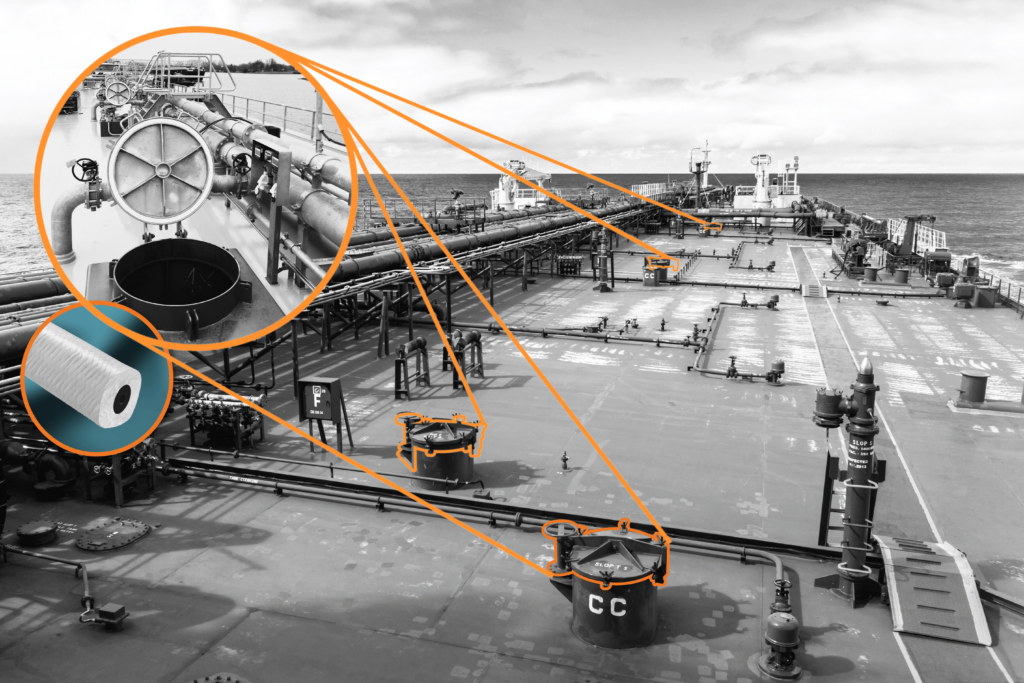

Beldam Crossley, a global leader in sealing solutions for critical industrial applications, has announced its DNV-certified Pilot® Lidpack® 3801L hatch seal – the only product of its kind recommended for use with Naphtha in crude oil transportation. This pioneering seal is proven in the marine industry for safety, environmental compliance, and cargo integrity.

With over 40,000 chemical tankers operating worldwide transporting hazardous cargoes such as crude oil, methanol, and benzene; the need for robust, leak-free sealing has never been greater. Beldam Crossley is the only seal manufacturer globally to manufacture recommended hatch seals for Naphtha, reaffirmed through DNV retesting certification every ten years and which is a game-changer for the industry.

The Lidpack® range, available in 3800 and 3801L, offers an energised rubber core and several proprietary materials including a chemically inert wrap of PTFE for maximum chemical resistance. Braided PTFE yarn for strength and abrasion resistance and outer layers of PTFE for total impermeability are other key USP’s of the range.

This results in zero leakage, from hatch lid operations which has earned the product certifications from both DNV and the U.S. Coast Guard, and Lloyds registered.

Designed for marine chemical and solvent transportation, Lidpack® sets a new industry benchmark for reliability, environmental stewardship, and onboard safety. In just 18 months, all major shipping companies in Istanbul have converted to Beldam Crossley seals, eliminating the risk of leaking hatches and avoiding fines linked to failed pressure build-up tests.

“Leaks not only endanger marine ecosystems and crew but also lead to significant financial penalties for the captain and the ship itself. A failed pressure test requires either immediate repair or vessels face costly delays and regulatory fines of 10% of the total cargo value which we have seen imposed into the thousands of pounds and leaving port delays, “said Lee O’Connor, Marine sales executive at Beldam Crossley.

In 2024 alone, Beldam Crossley resolved six major hatch leak incidents across six international fleets, reinforcing its commitment to global maritime safety. The company also supports retrofit solutions for vessels worldwide, helping operators remain compliant and efficient.

Additionally, the Lidpack® solution helps prevent the costly sea and rain water ingress into the cargo holds contaminating shipments, hatch leakage and ingress are plaguing the sea transport industry, Beldam Crossley Ltd Lidpack is the cure.

Beldam Crossley continues to lead with innovation and responsibility, providing cutting-edge solutions that protect cargo, crew, and the marine environment.

For more information, visit www.beldamcrossley.co.uk