Subsea engineers now have access to an innovative bearing solution with unmatched compressive strength, ultra-low friction, and zero maintenance requirements.

Beldam Crossley, a UK-based engineering specialist in high-performance polymer sealing and bearing components, has officially launched its new subsea Crossflon® slide bearings that are powered by the proprietary Crossflon® XS material. Developed over a three-year period with an R&D investment exceeding £150,000, the range is set to redefine standards in subsea bearing performance.

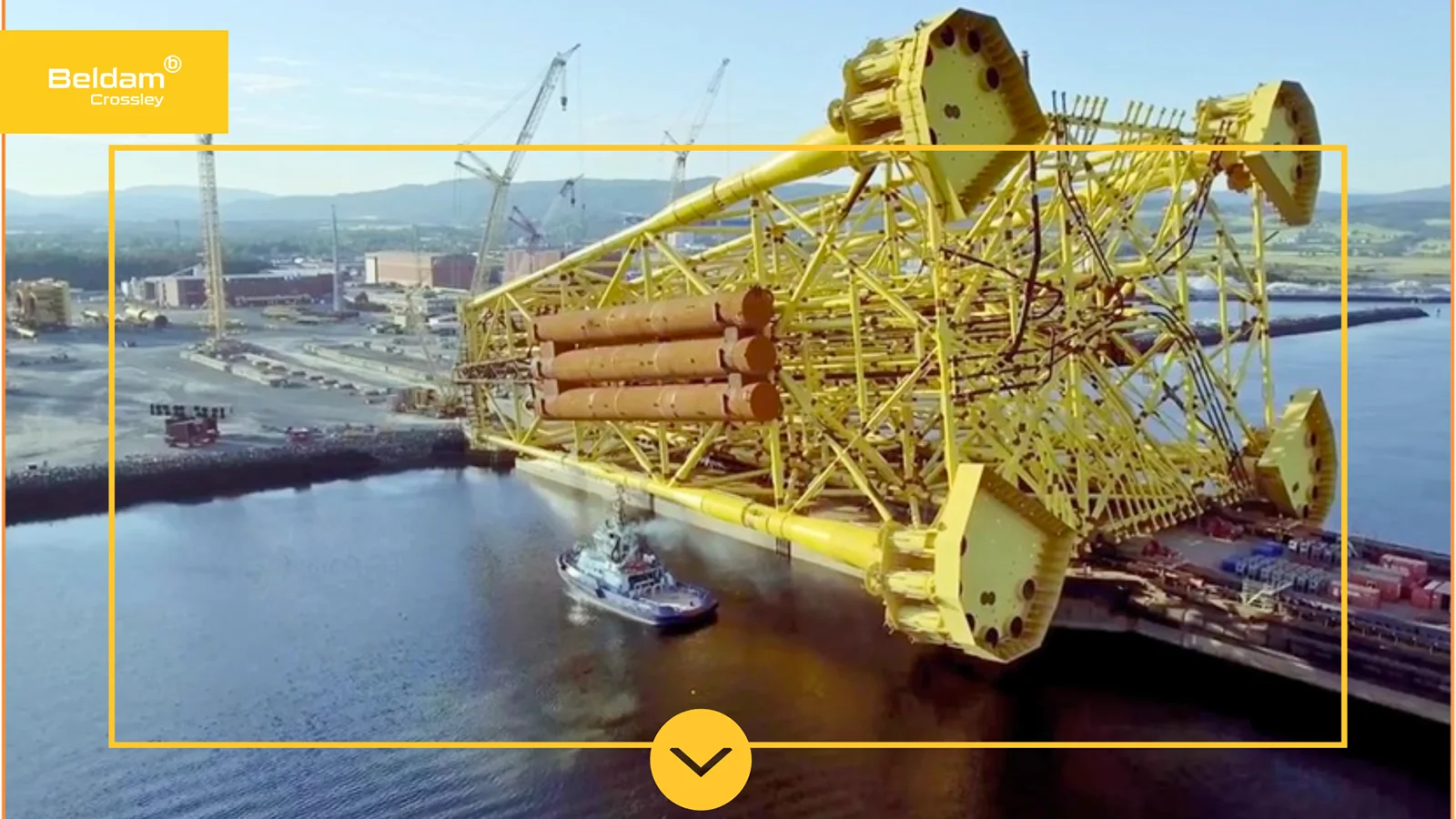

The launch marks a strategic milestone for Beldam Crossley as it extends its engineered polymer expertise into the subsea sector. This new product is already in active use within a major offshore installation off the coast of Angola, operating at depths of up to 780 metres.

At the heart of this new pioneering product, exclusive to Beldam Crossley is Crossflon® XS, a proprietary filled PTFE developed in-house to solve one of the industry’s most persistent challenges: how to combine extreme compressive strength with the ultra-low friction required in subsea environments.

Where traditional PTFE materials typically force a compromise between load bearing capacity and coefficient of friction, Crossflon® XS breaks the mould, delivering static values as low as 0.03 (on par with virgin PTFE) while withstanding compressive loads up to 75MPa, which is nearly three times that of conventional glass filled PTFE.

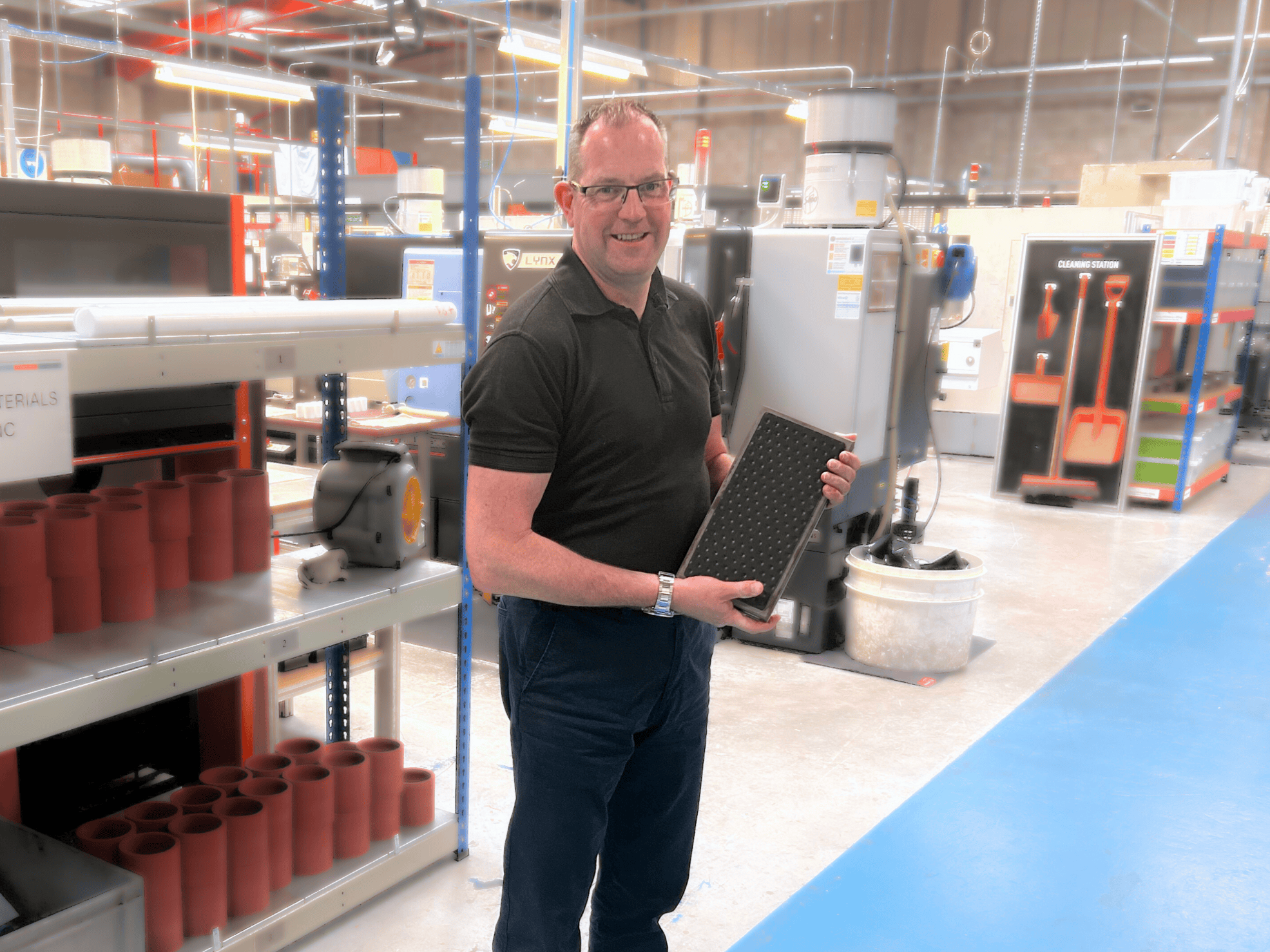

Gareth Holt, Sales Director at Beldam Crossley said: “This is a world-first and we are beyond proud in bringing this proven solution to market. There is no other PTFE-based material we’re aware of on the market that can perform like Crossflon® XS. We’ve created a genuinely unique solution that is proven, tested and now installed in one of the harshest environments on Earth. It really is a game changer for businesses.”

Incorporating Crossflon® XS into Beldam Crossley’s established slide bearing technology, the new subsea bearings are purpose-built for applications such as flowline end terminations (FLETs), in-line tees (ILTs), pipeline end manifolds (PLEMs) and pipeline end terminations (PLETs). These components play critical roles in subsea processing, often in SURF-related projects (Subsea Umbilicals, Risers, and Flowlines).

Key features of these new subsea Crossflon® slide bearings include maintenance free operation over an extended period, near-zero water absorption and weldable construction, thus eliminating the need for bolted connections. In addition, with Beldam Crossley’s in-house design and testing facilities, they can be tailored to bespoke project needs.

Such Crossflon® slide bearings were used on a subsea installation of the coast of West Africa, where they where they were subjected to rigorous real-world testing conditions. The project, has opened doors to conversations with major energy and EPC contractors globally.

Engineered in Bolton, the subsea Crossflon® slide bearings launch also underscores Beldam Crossley’s long-standing expertise in PTFE innovation. The company was among the first in the UK to process PTFE over 60 years ago and has since developed a broad range of proprietary grades under the Crossflon® brand.

Gareth added: “This isn’t just a new product, it’s a strategic leap that will re-define subsea engineering. It validates years of R&D investment and showcases what British engineering can achieve when we push the boundaries of materials science.”

Following the successful Angola deployment, Beldam Crossley has seen record sales growth, with PTFE-based bearing systems exceeding £2 million in revenue in 2024 alone; a figure set to rise as demand for high-performance subsea materials grows across oil, gas, and renewable sectors.